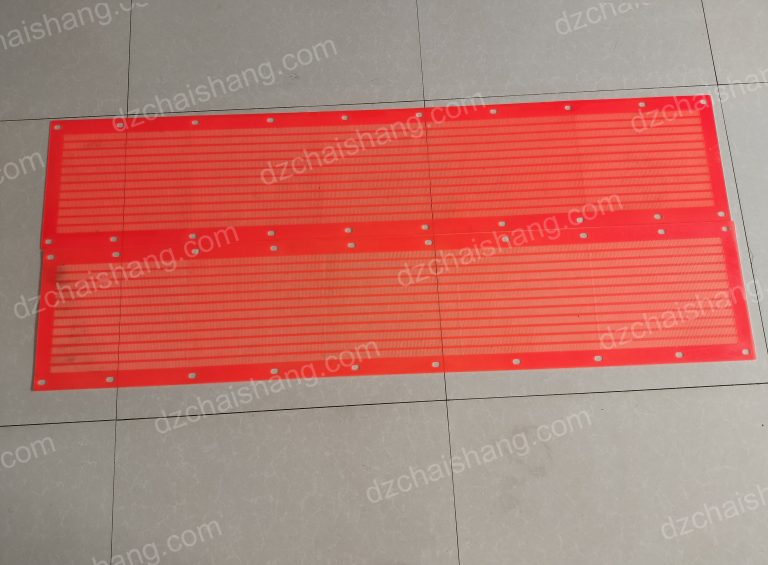

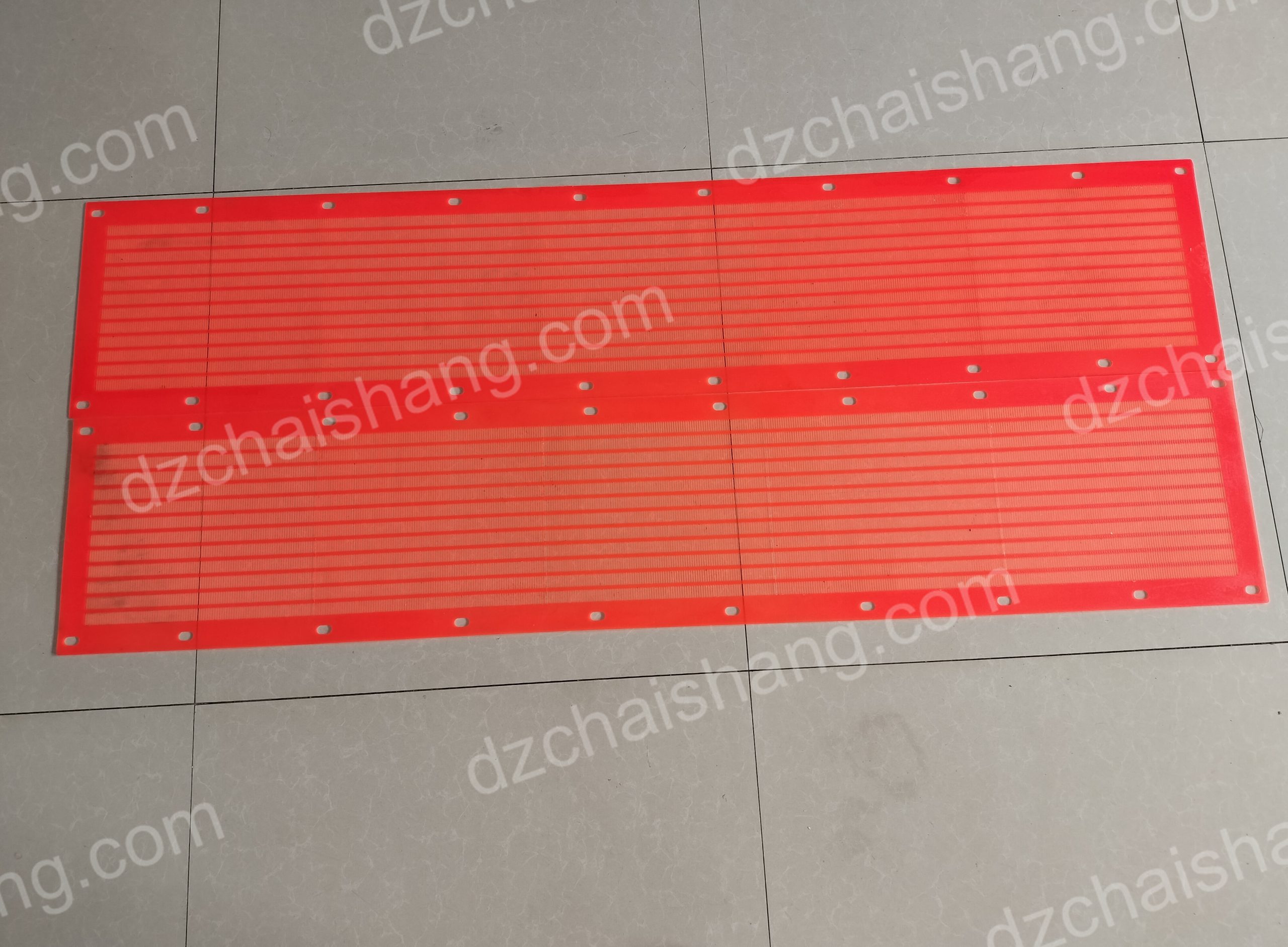

聚氨酯筛网ODM、聚氨酯筛网脱水制造商

مزاياشاشةسلكالبولي يوريثين ODM للتطبيقات الصناعية

أصبحت شاشات أسلاك البولي يوريثينبشكل متزايد الخيار المفضل للتطبيقات الصناعية نظرًالمتانتها وكفاءتهاالاستثنائية。 كمادة، يُعرفالبولي يوريثينبقوته ومرونته،ممايجعله مثاليًاللاستخدامفي عمليات الفحصالمختلفة。 تعملالقدرةعلىتخصيص هذهالشاشاتمنخلال خدمات تصنيع التصميم الأصلي(ODM)علىتعزيز ملاءمتهاللاحتياجات الصناعيةالمحددة،مما يوفر حلاً مخصصًا يمكنه تحسين أداء وإنتاجية عمليات الفحصبشكل كبير.

إحدىالمزايا الأساسيةلاستخدامسلك البولي يوريثين الشاشات المستخدمةفي التطبيقات الصناعيةهي مقاومتهاالفائقة للتآكل。 علىعكسالشاشات السلكيةالتقليدية المصنوعةمنالمعادن مثلالفولاذ،فإنشاشات البولي يوريثينأقل عرضةللتآكل。 وهذا مفيد بشكل خاص في الصناعات التي تتعرض فيهاالشاشاتلأحمال ثقيلةوموادكاشطة。 تعملالمتانةالمحسنة للبولي يوريثينعلى إطالةعمرالشاشات،مما يقللالحاجةإلىعمليات استبدالمتكررة وبالتاليخفضتكاليف الصيانة。

علاوةعلىذلك، توفر الشاشات المصنوعة منأسلاكالبولي يوريثينمقاومةممتازة للتآكلوالعوامل البيئيةالأخرى。 وهذايجعلهامناسبة للاستخدامفيمجموعة واسعةمنالظروف،بمافي ذلكالبيئاتالرطبة والمسببةللتآكل。 بالنسبةلصناعاتمثل التعدينواستغلال المحاجر، حيث تتعرض الشاشات غالبًالعناصر قاسية، يوفر البولي يوريثينحلاًموثوقًا يمكنهتحملقسوةمثلهذه التطبيقاتالصعبة。 تساعدمرونةالمادةفي الحفاظعلىسلامة الشاشات،ممايضمن الأداءالمتسقمعمرور الوقت。

الميزةالمهمة الأخرى لشبكات أسلاك البولي يوريثينهي مرونتها。 تتيح القدرة على تخصيص هذهالشاشاتمنخلال خدمات ODM للمصنعين تصميم المنتجات التي تلبي المتطلبات المحددة لمختلفالصناعات。 سواء أكان الأمر يتعلق بتغيير سمك الشاشات أو حجم فتحة العدسة أو نمطها، يمكن للمصنعين إنشاءحلولمخصصةتعمل علىتحسينعمليةالفحص لموادأوظروفمعينة。 لايؤديهذاالمستوىمن التخصيصإلىتعزيز كفاءةعمليةالفحص فحسب، بل يساهم أيضًا في تحسينمراقبةالجودة واتساقالمنتج。

تعد شاشات سلك البولي يوريثينعنصرًا أساسيًافيأنظمةنزح المياهالمستخدمةفي مختلفالصناعات،بمافي ذلكالتعدينوالزراعة ومعالجةمياهالصرف الصحي。 كشركةمصنعةلأنظمةنزح الماءمنمنخلالبولي يوريثين،منالضروري فهمالميزاتالرئيسية التيتجعلهذهالأنظمة فعالةللغايةوفعالةفي فصلالموادالصلبةعن السوائل。

إحدى السمات الأساسية لأنظمة نزح الماء من منخلالبولييوريثينهي متانتهاالاستثنائية。 البولي يوريثينمادة قويةمعروفةبمقاومتها للتآكلوالتآكل。 وهذايجعلهامثالية للاستخدامفيالبيئات القاسيةحيثتتعرض الشاشات لأحمالثقيلة وموادكاشطة。 تضمن مرونة مادة البولي يوريثينأنتتمتع الشاشات بعمرافتراضي أطول، مما يقلل الحاجة إلىعملياتاستبدال متكررةوبالتاليخفض تكاليفالصيانة。 تم تصميم شاشات أسلاك البولي يوريثينبدقة لتوفيرأقصىقدرمن تصريفالمياهمع الاحتفاظبالمواد الصلبة。 تسمح الخصائصالفريدة للبولي يوريثين بالمرونةالمثالية، ممايعززقدرةالشاشة علىالتعاملمعمعدلات التغذيةالمختلفة واتساقالمواد。 تضمنهذهالمرونةالفصل الفعالونزحالمياه، مما يؤدي إلى تحسين جودة المنتج وتقليلمحتوى الرطوبةفيالناتج النهائي。

علاوةعلىذلك، توفر أنظمة نزح المياه منغربالالبولي يوريثينمقاومةممتازة للتآكل。 علىعكسالشاشات المعدنية،لايصدأ البولي يوريثينأو يتآكلعندتعرضهللماء أوالموادالكيميائية。 تعتبرهذهالمقاومة للتآكلمفيدةبشكلخاص في الصناعات التي تكون فيهاالشاشاتعلىاتصال دائمبالموادالمسببة للتآكل。 باستخدامشاشاتالبولي يوريثين،يمكن للمصنعينمنعتلوث الموادالصلبة المنفصلةوإطالةعمر الخدمةالإجماليلنظام نزح المياه.

بالإضافة إلىالمتانةوالأداء ومقاومةالتآكل،فإن أنظمةنزحالمياهمن غربالالبولييوريثين معروفةأيضًابتعدد استخداماتها。 يمكنتخصيصهذهالأنظمة لتلبيةمتطلبات الصناعةالمحددةوتكون قادرةعلىالتعاملمع مجموعةواسعةمن المواد، بدءًامن الجسيمات الدقيقةوحتى الركامالكبير。 يمكنللمصنعينتصميم الغرابيلبأحجام وأشكالمختلفةللفتحة، اعتمادًاعلىالمستوى المطلوبمنالترشيح وخصائص المواد التي تتم معالجتها。

علاوةعلى ذلك، فإن تركيب وصيانة أنظمةنزحالمياهمن منخلالبولييوريثين أمربسيطنسبيًا。 إنطبيعةمادةالبولي يوريثينخفيفةالوزن تجعلمنالسهلالتعامل مع الشاشات وتركيبها، ممايقللمنتكاليف العمالةووقتالتوقفعن العمل。 كماتمتبسيطالصيانة نظرًاللمتانة المتأصلةللمادة ومقاومتهاللانسداد。 عادةمايكونالتنظيف والفحصالمنتظمكافيين للحفاظعلىتشغيل النظامبكفاءة。

في الختام، توفر أنظمة نزحالمياهمنمنخل البولي يوريثينالعديد منالفوائدالتيتجعلها الخيار المفضللمختلف الصناعات。 وتساهممتانتها، وقدراتهاالعالية الأداء في نزح المياه، ومقاومتهاللتآكل، وتعدد استخداماتها، وسهولةصيانتها،في فعاليتهافيفصلالمواد الصلبةعنالسوائل。 ومعاستمرارالشركات المصنعةفيابتكار وتحسينهذهالأنظمة، فمنالمرجحأنتصبحأكثر تكاملاً مع العمليات الصناعيةالتيتتطلب حلولموثوقةوفعالة لنزحالمياه。 منخلالفهمالميزات الرئيسيةلأنظمةنزح المياهمنمنخلالبولي يوريثينوالاستفادة منها، يمكن للمصنعين تحسينعملياتهموتحقيق نتائج أفضل من حيث جودة المنتج والكفاءة التشغيلية。

聚氨酯丝网是采矿、农业和废水处理等各个行业使用的脱水系统的重要组成部分。作为聚氨酯筛分脱水系统的制造商,了解使这些系统能够高效、高效地从液体中分离固体的关键特征至关重要。

聚氨酯筛分脱水系统的主要特征之一是其卓越的耐用性。聚氨酯是一种坚固的材料,以其耐磨损、磨损和撕裂而闻名。这使得它非常适合在屏幕承受重负载和磨料的恶劣环境中使用。聚氨酯的弹性确保筛网具有更长的使用寿命,减少频繁更换的需要,从而降低维护成本。

这些系统的另一个显着特点是其高性能脱水能力。聚氨酯丝网经过精密设计,可在保留固体的同时提供最大程度的排水。聚氨酯的独特性能可实现最佳的灵活性,从而增强筛网处理不同进料速率和材料稠度的能力。这种灵活性确保了高效的分离和脱水,从而提高了产品质量并降低了最终输出中的水分含量。

此外,聚氨酯筛脱水系统具有出色的耐腐蚀性。与金属筛网不同,聚氨酯在接触水或化学品时不会生锈或腐蚀。这种耐腐蚀性对于筛网经常与腐蚀性物质接触的行业特别有利。通过使用聚氨酯筛网,制造商可以防止分离的固体受到污染,并延长脱水系统的整体使用寿命。

除了耐用性、性能和耐腐蚀性之外,聚氨酯筛网脱水系统还以其多功能性而闻名。这些系统可以定制以满足特定的行业要求,并且能够处理从细颗粒到大骨料的各种材料。制造商可以根据所需的过滤水平和所处理材料的特性,设计不同孔径尺寸和形状的筛网。

此外,聚氨酯筛网脱水系统的安装和维护相对简单。聚氨酯的轻质特性使筛网易于搬运和安装,减少了劳动力成本和停机时间。由于该材料固有的耐用性和抗堵塞性,维护也得到简化。定期清洁和检查通常足以保持系统高效运行。

总而言之,聚氨酯筛脱水系统具有众多优点,使其成为各个行业的首选。它们的耐用性、高性能脱水能力、耐腐蚀性、多功能性和易于维护性有助于其有效地从液体中分离固体。随着制造商不断创新和改进这些系统,它们可能会成为需要可靠、高效脱水解决方案的工业流程中不可或缺的一部分。通过了解和利用聚氨酯筛脱水系统的主要特征,制造商可以优化其运营并在产品质量和运营效率方面取得更好的成果。