中国筛网,矿用筛网报价,矿用筛网

استكشافعمليةتصنيع شبكةالغربلةالصينية

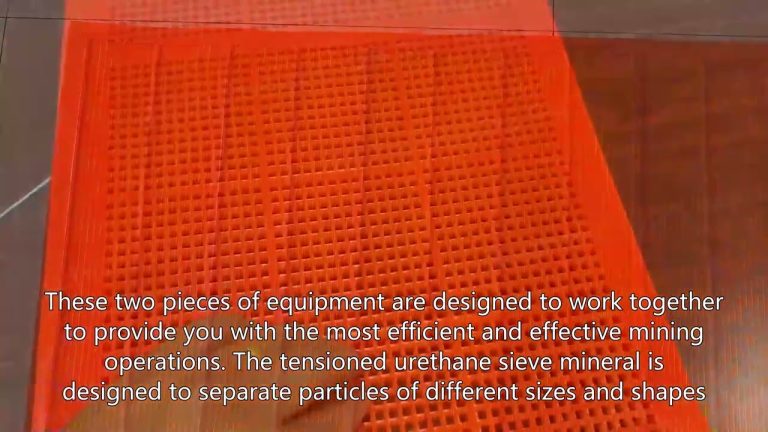

شبكةالشاشة،فيأبسط صورها، هي نوع من المواد المنسوجةالمصنوعةمن أسلاكمعدنيةمتقاطعة。 يمكن تعديل حجم الفتحات بينالأسلاك،والمعروف باسم عدد الشبكات، لتلبيةمتطلباتمحددة。 في صناعة التعدين، يتم استخدامشبكةالشاشة لفصلأحجاممختلفةمن الخام، مع تحديد عدد الشبكات حجم الجزيئات التي يمكن أن تمر من خلالها。

تبدأعملية تصنيعشبكةالشاشة الصينيةباختيار الموادالخام。 عادة ما يتم استخدام الفولاذعاليالجودة بسببقوتهومتانته。 يتم بعد ذلك تسخين الفولاذ إلى درجة حرارة عاليةويتمسحبهإلى أسلاكرفيعة。 يتم التحكم في سمك هذه الأسلاكبعنايةللتأكد منأنالمنتجالنهائي يحتوي على عدد الشبكات المطلوب。

بمجردإعداد الأسلاك،يتمنسجها معًاباستخدامآلات متخصصة。 يتم ترتيب الأسلاك بشكل متعامد مع بعضها البعض ويتملحامالنقاطالتي تتقاطعفيهامعًا لإنشاءهيكلقويومستقر。 تتميزعمليةالنسيجهذه بالدقةالعالية،مع معايرةالماكينةلضمان أنالفتحاتبينالأسلاك موحدةفي الحجم.

بعد عمليةالنسيج،تخضع شبكةالغرباللسلسلةمن فحوصات مراقبةالجودة。 تم تصميم هذه الفحوصات لتحديد أي عيوب في الشبكة، مثل الفتحات غيرالمنتظمةأو اللحاماتالضعيفة。 إذاتمالعثورعلىأي عيوب، يتم إصلاح الشبكة أوالتخلصمنهالضمان إرسالالمنتجاتعالية الجودةفقطإلىالسوق。

أحدالأسبابالرئيسية التي تجعل شبكة الشاشة الصينيةتحظىبتقدير كبيرفيصناعةالتعدين يرجعإلىمتانتها。 إن الفولاذ عالي الجودة المستخدمفيإنتاجه، إلىجانبدقةعملية النسيج، يؤدي إلى منتج يمكنهتحملالظروف القاسيةالموجودةفي المناجم。 تعني هذه المتانة أن شبكةالشاشةتتطلب استبدالًاأقل تكرارًا،ممايقللوقت التوقفعنالعملويزيد الإنتاجية.

هناكسببآخر لشعبيةشبكةالشاشة الصينيةوهوتعدد استخداماتها。 القدرةعلىضبطعدد الشبكات تعني أنه يمكن استخدامهالفصلمجموعة واسعةمنأحجام الجسيمات。 تسمح هذهالمرونة لشركات التعدين باستخدامنفسالنوعمن شبكات الغربلةلخامات مختلفة، ممايبسط عملياتهاويقلل التكاليف。

فيالختام، تعد عملية تصنيع شبكات الغربالالصينيةعملية معقدة،وتتضمن الاختيارالدقيق للمواد الخاموالدقة تقنيات النسيج، وفحوصات صارمةلمراقبة الجودة。 والنتيجةهيمنتجمتين ومتعدد الاستخدامات وذوقيمةعاليةفيصناعة التعدين。 معاستمرارنموالطلب على شبكات الشاشة، من المقررأنيستمردور الصينكشركةمصنعة رائدة。 لذا، إذا كنت في السوق لشراءشبكةشاشات الألغام،ففكرفي الحصولعلىعرضأسعارمن شركةتصنيعصينيةذات سمعةطيبة。 قدتتفاجأبالجودة والقيمةالتييمكنهم تقديمها。

إنفهمأسعارشبكات الشاشالخاصة بالألغام، خاصةتلك المصنعة في الصين، يمكن أنيكونمهمةمعقدة。 ويرجعذلكإلىالعوامل العديدةالتيتؤثرعلى التكلفة،بمافيذلك المواد المستخدمةوحجم الشبكةوعمليةالتصنيع وظروفالسوقالحالية。 ومع ذلك، مع الفهم الشامللهذهالعوامل، منالممكناتخاذقرار مستنيرعندطلبعروض أسعارلشبكاتمنخل الألغام。

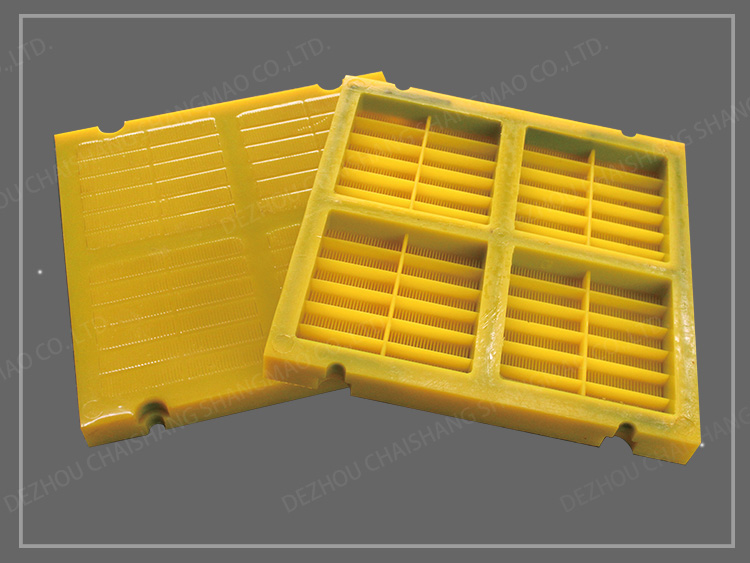

تعدالمواد المستخدمةفيإنتاج شبكةمنخلالألغامأحد أهمالعواملالتيتؤثر علىسعرها。 المواد الأكثر شيوعًا المستخدمةهيالفولاذ المقاومللصدأ والفولاذعاليالكربون والبولييوريثين。 الفولاذ المقاومللصدأ متينللغايةومقاوم للصدأ، مما يجعله خيارًامثاليًا لعمليات التعدينفي الظروفالرطبةأو الرطبة。 ومنناحيةأخرى،فإن الفولاذعاليالكربون معروفبقوةالشد العاليةوالمتانة،مما يجعلهمناسبًالعمليات التعدينالثقيلة。 تتميزشبكاتالبولي يوريثينبأنهاخفيفة الوزنومرنة،مما يجعلها سهلة التركيب والصيانة。 يعتمد اختيارالمادة علىالمتطلباتالمحددة لعمليةالتعدين،وكل مادةتأتيبسعر مختلف。

يلعبحجمالشبكة أيضًادورًاحاسمًافي تحديدالسعر。 يتم قياس الحجم عادة من حيث عدد الفتحات في البوصةالخطية。 وكلماكانت الفتحات أصغر، زاد عدد الأسلاك المستخدمة،وبالتالي ارتفعتالتكلفة。 بالإضافةإلىذلك،فإن الأبعادالإجمالية للشبكة، مثلالطول والعرض، ستؤثر أيضًا علىالسعر。 تتطلبالشبكاتالأكبر حجمًاالمزيدمنالمواد والعمالةلإنتاجها، ممايزيدمنالتكلفة。

تعدعمليةالتصنيع عاملاً آخر يؤثر على سعر شبكةغربالالمنجم。 تتضمنالعمليةعدة خطوات، بما في ذلك سحب الأسلاكوالنسيجأو اللحاموالقطع والتشطيب。 وتتطلبكلخطوةآلات متخصصةوعمالةماهرة، ممايزيدمنالتكلفة。 علاوة على ذلك، فإن أي تخصيص إضافي أو ميزات خاصة، مثل خصائص مكافحة الانسدادأوالتنظيف الذاتي، ستؤدي أيضًا إلىزيادةالسعر。

يمكن أن تؤثر ظروف السوق أيضًاعلىسعرشبكة غربالالألغام。 يمكنلعواملمثلالعرض والطلبللمواد، والتقلباتفيتكلفة المواد الخام، والتغيرات في تكاليف العمالة أن تؤثر جميعها علىالسعرالنهائي。 علىسبيلالمثال،إذا كانت هناك زيادة مفاجئة في الطلب على الفولاذ المقاومللصدأ،فمن المرجحأنيرتفعسعر شبكةالفولاذالمقاوم للصدأ。

عند طلب عرض أسعار لشبكة غربالالألغام،من الضروري مراعاةكلهذه العوامل。 يُنصحأيضًابطلبعروض الأسعارمنالعديدمن الشركات المصنعة للحصولعلىفهمأفضل لسعرالسوق。 تذكر أن أرخص عرض أسعار قد لا يكون دائمًا هو الخيارالأفضل。 منالضروريمراعاةجودة الشبكةوسمعةالشركة المصنعةأيضًا。

في الختام، يتضمن فهم تسعيرشبكةغربلة الألغامفهمًاشاملاً للعواملالتيتؤثرعلى تكلفتها。 منخلالالنظرفيالمواد والحجموعمليةالتصنيع وظروفالسوق،يمكنك اتخاذ قرار مستنير عند طلبعروضأسعارشبكة الشاشةالخاصة بالألغام。 لنيضمنهذاحصولكعلى أفضلقيمةمقابلأموالك فحسب، بل سيضمن أيضًا اختيارشبكةتلبي المتطلبات المحددة لعمليةالتعدينالخاصة بك.

制造工艺是影响矿用筛网价格的另一个因素。该过程涉及多个步骤,包括拉丝、编织或焊接、切割和精加工。每个步骤都需要专门的机械和熟练的劳动力,这增加了成本。此外,任何额外的定制或特殊功能,例如防堵塞或自清洁性能,也会增加价格。

市场状况也会影响矿筛网的价格。材料的供需、原材料成本的波动、劳动力成本的变化等因素都会影响最终的报价。例如,如果不锈钢的需求突然增加,不锈钢网的价格可能会上涨。

在索取矿用筛网报价时,必须考虑所有这些因素。还建议向多家制造商索取报价,以便更好地了解市场价格。请记住,最便宜的报价可能并不总是最好的选择。考虑筛网的质量和制造商的声誉至关重要。

总之,了解矿用筛网的定价需要全面了解影响其成本的因素。通过考虑材料、尺寸、制造工艺和市场条件,您可以在索取矿筛网报价时做出明智的决定。这不仅可以确保您物有所值,还可以确保您选择的网格能够满足采矿作业的特定要求。