中国石材筛分筛网供应商,振动筛筛网

مزايااستخداممورد شبكةغربلةالحجر الصيني للتطبيقات الصناعية

يقدمموردشبكةغربلة الحجرفي الصينمجموعة واسعةمنالفوائد للتطبيقاتالصناعية。 تمتصميمهذهالشاشات الشبكيةلفصلالمواد بكفاءةبناءًعلى الحجم، مما يجعلها مثاليةللاستخدامفي مختلفالصناعاتمثل التعدينوالبناء والزراعة。 ومنخلالاختيارمورد موثوقبهفيالصين،يمكن للشركات ضمانحصولها علىمنتجاتعالية الجودةومتينةوطويلة الأمد。

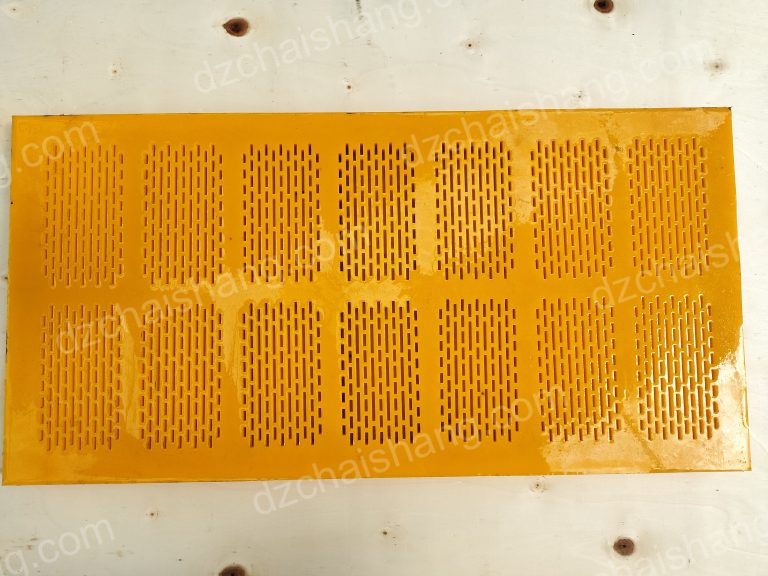

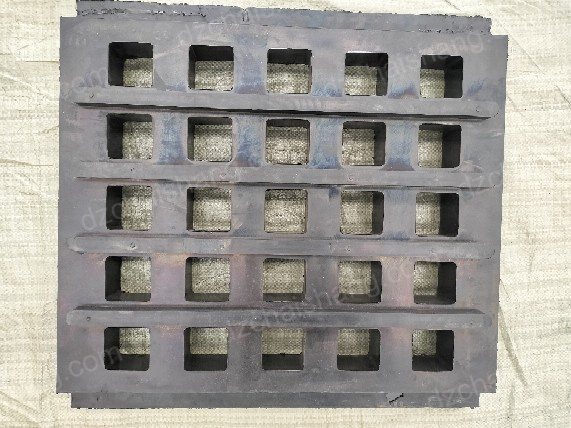

عندمايتعلقالأمر باختيارالشاشة الشبكيةالمناسبة للهزازات، هناكعدة عوامليجبمراعاتها لضمانالأداءوالكفاءة الأمثل。 أحد الاعتبارات الرئيسيةهومادة الشاشةالشبكية。 يقدم موردو شبكات غربلة الحجرفي الصينمجموعة متنوعة من المواد، بما في ذلك الفولاذ المقاوم للصدأ، والبولي يوريثين،والشبكات السلكيةالمنسوجة。 كلمادةلهاخصائصها وفوائدهاالفريدة، لذلكمنالمهماختيار المادةالتيتناسب احتياجاتكالخاصة.

تُعرفالشاشاتالشبكية المصنوعةمنالفولاذ المقاومللصدأ بمتانتهاومقاومتها للتآكل، مما يجعلها مثاليةللتطبيقات شديدةالتحمل。 كماأنهاسهلةالتنظيف والصيانة، مما يجعلها خيارًاشائعًالصناعات مثلالتعدينوالبناء。 منناحيةأخرى،تتميز شاشات شبكة البولي يوريثينبأنهاخفيفة الوزنومرنة،مما يجعلهامثالية للتطبيقات التي يكون فيهاالاهتزازمصدرقلق。 كماأنهامقاومةللتآكل والتآكل، ممايجعلها خيارًافعالاًمنحيث التكلفةللاستخدامعلى المدىالطويل。

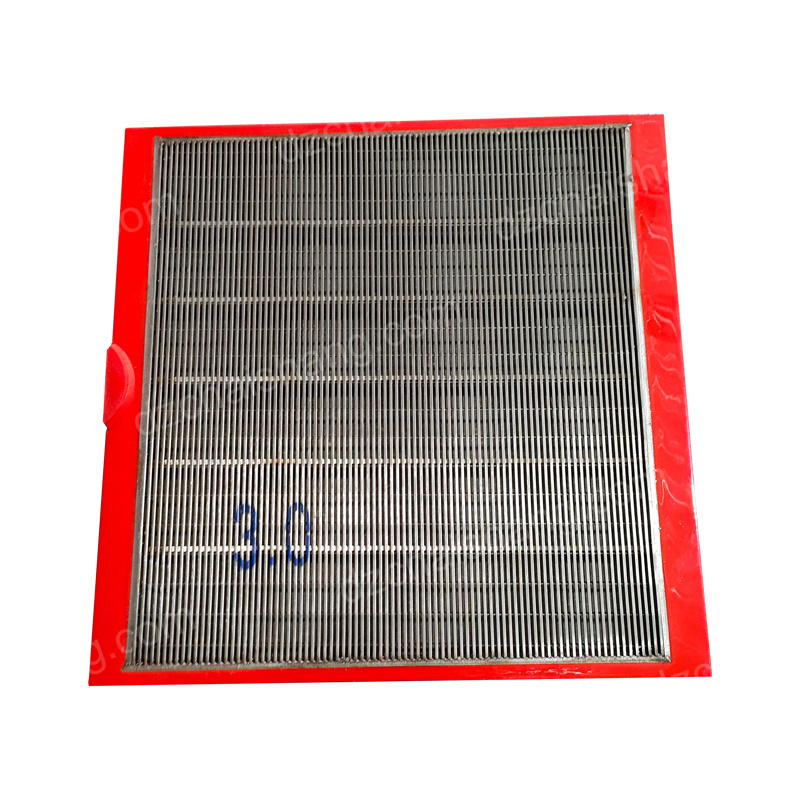

تعدالحواجزالشبكية السلكيةالمنسوجة خيارًاشائعًاآخر،حيث توفرمستوىعالٍمن الدقةوالدقةفيفصل الجسيمات。 وهي متوفرة في مجموعة واسعةمنأحجام الشبكات،ممايسمح بالتخصيصبناءًعلى متطلباتمحددة。 ومع ذلك، قد لا تكون متينةمثلشاشات الفولاذ المقاومللصدأ أوالبولييوريثين، لذلكمنالمهممراعاة مستوىالتآكلالذي ستتعرضله الشاشة。

بالإضافةإلى المادة، يعد حجم الشبكة أحدالاعتباراتالمهمة الأخرىعنداختيار الشاشة。 للهزازات。 يشيرحجمالشبكةإلىعدد الفتحات في كل بوصة في الشاشة، وتشير الأرقام الأعلىإلىفتحاتأصغر。 يعتمدحجمالشبكةالتي تختارهاعلىحجم الجزيئات التي تحتاج إلى فصلها، بالإضافة إلىمستوىالدقة المطلوب。 علىسبيلالمثال،سيكون حجم الشبكة الأصغر أكثر فعاليةفيفصلالجزيئات الدقيقة،بينماقديكون حجم الشبكة الأكبر أكثر ملاءمةللجسيمات الأكبرحجمًا。

هناكعاملآخريجب مراعاتهوهونوعالهزاز الذي ستستخدممعه الشاشةالشبكية。 تختلفمتطلبات الهزازات المختلفةمن حيث حجم الشاشة والمواد، لذلك من المهم اختيار شاشة متوافقة مع أجهزتكالمحددة。 قد تتطلب بعض الهزازات نوعًامعينًامن الشاشات، بينما قد يكون البعضالآخرأكثر تنوعًامنحيثالشاشات التي يمكنها استيعابها.

عنداختيار شاشة شبكية للهزازات، منالمهمأيضًامراعاة الجودةالإجمالية للشاشة。 ابحث عن مورد حسن السمعة يقدمشاشاتعالية الجودةمصممةلتدوم طويلاً。 يُعرفموردوشبكات غربلةالحجرفيالصين بجودتهموموثوقيتهم، لذلك يمكنك أن تثق في أنك تحصلعلىشاشةذاتأداء جيد وتلبي متطلبات تطبيقك。

في الختام، اختيار الشاشة الشبكية المناسبةللهزازاتأمر ضروري لتحقيقالأداء الأمثلوالكفاءة。 ضعفياعتباركعواملمثل المادةوحجمالشبكة وتوافق الهزاز والجودة الشاملةعنداتخاذ قرارك。 منخلالتخصيصالوقت لتقييمخياراتكبعناية واختيارالشاشةالتي تلبي احتياجاتك الخاصة، يمكنك التأكد منأنجهازالهزازالخاص بكيعملبأفضلحالاته ويقدمنتائجموثوقة。

不锈钢筛网以其耐用性和耐腐蚀性而闻名,使其成为重型应用的理想选择。它们还易于清洁和维护,使其成为采矿和建筑等行业的热门选择。另一方面,聚氨酯网筛重量轻且灵活,非常适合需要关注振动的应用。它们还耐磨损,使其成为长期使用的经济高效的选择。

编织丝网筛网是另一种流行的选择,可提供高水平的颗粒分离精度和准确度。它们有多种网格尺寸可供选择,可以根据特定要求进行定制。然而,它们可能不如不锈钢或聚氨酯筛网那么耐用,因此考虑筛网的磨损程度很重要。

除了材料之外,筛网尺寸是选择筛网时的另一个重要考虑因素对于摇床。目数是指筛网上每英寸的孔数,数字越大,孔越小。您选择的网格尺寸取决于您需要分离的颗粒的尺寸以及所需的精度水平。例如,较小的筛孔尺寸在分离细颗粒方面会更有效,而较大的筛孔尺寸可能更适合较大的颗粒。

另一个需要考虑的因素是您将使用网筛的摇床类型。不同的振动筛对筛网尺寸和材料有不同的要求,因此选择与您的特定设备兼容的筛网非常重要。一些摇床可能需要特定类型的筛网,而其他摇床可能在可容纳的筛网方面更加通用。

为摇床选择网筛时,考虑筛网的整体质量也很重要。寻找信誉良好的供应商,提供经久耐用的高品质屏幕。中国石料筛分筛网供应商以其质量和可靠性而闻名,因此您可以相信您所获得的筛网性能良好并能满足您的应用需求。

总之,为振动筛选择合适的筛网对于实现最佳性能和效率至关重要。做出决定时,请考虑材料、筛孔尺寸、振动筛兼容性和整体质量等因素。通过花时间仔细评估您的选择并选择满足您特定需求的屏幕,您可以确保您的摇床以最佳状态运行并提供可靠的结果。