厂家振动筛聚氨酯细板矿物,厂家振动器PU模块筛矿石

استكشافكفاءةمعادن لوحةاليوريثان الدقيقة في شاكر المصنع

يعد دور الغربال المعياري PUالهزازالخاص بالشركةالمصنعةفي معالجةالخامأمرًا بالغ الأهمية، وهو موضوعيستحقنظرةفاحصة。 هذهالتكنولوجيا المبتكرة، والمعروفة أيضًاباسممعدنلوحة اليوريثانالدقيقة الهزازةفيالمصنع، أحدثت ثورة في الطريقة التي نعالج بها الخامات، مما يؤدي إلى زيادةالكفاءة والإنتاجيةفيصناعة التعدين。 ، هي قطعة من المعدات المستخدمةفيصناعة التعدينلفصلأنواع مختلفةمنالخامات。 لقدتمتصميمهللتعامل معمجموعةواسعةمن المواد، بدءًامن الجسيمات الدقيقةوحتى الصخورالكبيرة،وهو فعالبشكلخاصفيفصل الخامات عن المواد غير المرغوبفيها。 الغربالمصنوعمنمادة البولي يوريثين(PU)، وهي مادةمعروفةبمتانتها ومقاومتهاللتآكل。 وهذايجعلهامثالية للاستخدامفيبيئات التعدينالقاسيةحيث غالبًاماتتعرض المعدات لظروف قاسية。

تتضمنعملية معالجةالخامعدة خطوات، بما في ذلك الاستخراج والسحق والطحنوالفصل。 PU الهزازالخاصبالشركة المصنعةدورًاحاسمًا فيمرحلةالفصل。 يعملعنطريقاستخدام الاهتزازلتحريكالخام فوقالمنخلالذييحتوي علىثقوببأحجاممختلفة。 تسقطالجزيئاتالصغيرة منخلالالثقوب،بينما تبقى الجزيئات الأكبر فيالأعلى。 يتيح ذلك لعمال المناجم فصلالخامالثمينعن مواد النفايات، مما يحسنكفاءةالعملية ويقللكميةالنفايات المنتجة。

إحدىالمزايا الرئيسيةللغربال المعياري PUالهزازالخاص بالشركةالمصنعةهو نمطيته。 وهذايعنيأنهيمكن تعديلهبسهولةللتعامل معأنواعمختلفةمن الخامات وأحجاممختلفة منالجزيئات。 هذهالمرونةتجعلها أداةقيمةفيصناعة التعدين، حيث يمكن أن تختلف الظروف بشكل كبير منموقعإلىآخر。 علاوةعلىذلك،فإن استخدامالبولي يوريثانفيبناء الغرباليضمنقدرتهعلى تحملقسوةبيئة التعدين،ممايقلل الحاجةإلىالاستبدال والصيانة المتكررة。

يساهم PU الهزازأيضًافي استدامةصناعةالتعدين。 。 ومنخلالتحسينكفاءة معالجةالخام،فإنه يقللمنكميةالنفايات المنتجةوالطاقة اللازمةللعملية。 هذالايوفرأموالشركات التعدينفحسب،بليساعد أيضًافي تقليلالتأثير البيئي لعمليات التعدين。

إنمتانتهاومرونتها وكفاءتهاتجعلهاأداة لاتقدربثمنلعمال المناجم。 بينمانواصلالبحثعن طرقلتحسيناستدامة وكفاءةصناعةالتعدين، فإنالتقنياتمثل PU الهزازالخاصبالشركة المصنعةسوفتلعببلاشك دورًامتزايدالأهمية.

制造商振动器PU组合筛在矿石加工中的作用至关重要,是一个值得仔细研究的主题。这项创新技术也称为工厂振动筛聚氨酯细板矿物,彻底改变了我们加工矿石的方式,从而提高了采矿业的效率和生产率。

制造商振动器 PU 模块化筛或工厂振动筛聚氨酯细板矿物,是采矿业中用于分离不同类型矿石的设备。它设计用于处理从细颗粒到大岩石的各种材料,并且在将矿石与不需要的材料分离方面特别有效。该筛子由聚氨酯 (PU) 制成,这种材料以其耐用性和耐磨损性而闻名。这使得它非常适合在恶劣的采矿环境中使用,在这些环境中,设备经常处于极端条件下。

矿石加工过程涉及多个步骤,包括提取、破碎、研磨和分离。制造商振动器 PU 模块化筛在分离阶段起着至关重要的作用。它的工作原理是利用振动将矿石移过筛子,筛子上有不同尺寸的孔。较小的颗粒从孔中落下,而较大的颗粒则留在顶部。这使得矿工能够将有价值的矿石从废料中分离出来,从而提高流程效率并减少产生的废物量。

制造商振动器 PU 模块化筛的主要优势之一是其模块化。这意味着它可以轻松调整以处理不同类型的矿石和不同尺寸的颗粒。这种灵活性使其成为采矿业中的宝贵工具,因为不同地点的条件可能存在很大差异。此外,筛子结构中使用 PU 可确保其能够承受采矿环境的严酷,从而减少频繁更换和维护的需要。

制造商振动器 PU 模块化筛子还有助于采矿业的可持续发展。通过提高矿石加工效率,减少了产生的废物量和加工过程所需的能源。这不仅为采矿公司节省了资金,还有助于减少采矿作业对环境的影响。总之,制造商振动器 PU 模块化筛或工厂振动器聚氨酯细板矿物在矿石加工行业中发挥着至关重要的作用。其耐用性、灵活性和效率使其成为矿工的宝贵工具。随着我们不断寻求提高采矿业可持续性和效率的方法,制造商振动器 PU 模块化筛等技术无疑将发挥越来越重要的作用。

The role of a manufacturer vibrator PU modular sieve in ore processing is a critical one, and it is a subject that deserves a closer look. This innovative technology, also known as a factory shaker urethane fine panel mineral, has revolutionized the way we process ores, leading to increased efficiency and productivity in the mining industry.

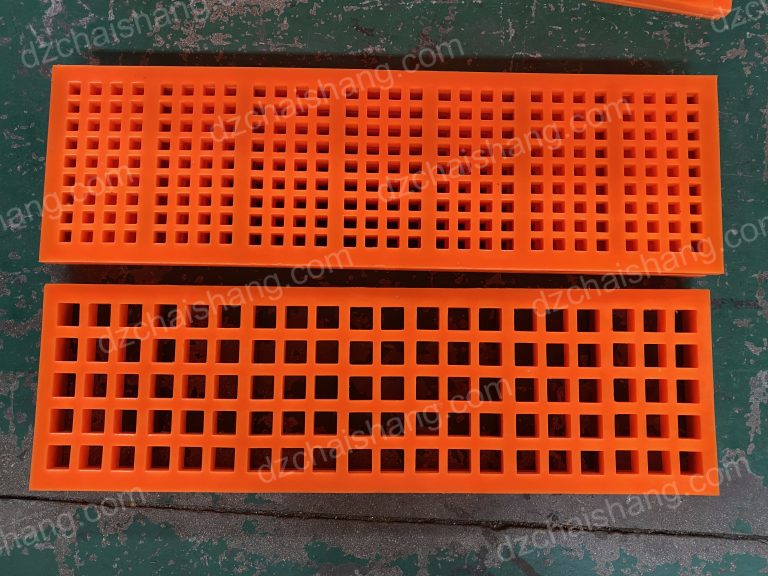

The manufacturer vibrator PU modular sieve, or factory shaker urethane fine panel mineral, is a piece of equipment used in the mining industry to separate different types of ores. It is designed to handle a wide range of materials, from fine particles to large rocks, and it is particularly effective at separating ores from unwanted materials. The sieve is made from polyurethane (PU), a material known for its durability and resistance to wear and tear. This makes it ideal for use in harsh mining environments where equipment is often subjected to extreme conditions.

The process of ore processing involves several steps, including extraction, crushing, grinding, and separation. The manufacturer vibrator PU modular sieve plays a crucial role in the separation stage. It works by using vibration to move the ore over the sieve, which has holes of varying sizes. The smaller particles fall through the holes, while the larger ones remain on top. This allows miners to separate the valuable ore from the waste material, improving the efficiency of the process and reducing the amount of waste produced.

One of the key advantages of the manufacturer vibrator PU modular sieve is its modularity. This means that it can be easily adjusted to handle different types of ores and different sizes of particles. This flexibility makes it a valuable tool in the mining industry, where conditions can vary greatly from one site to another. Furthermore, the use of PU in the construction of the sieve ensures that it can withstand the rigors of the mining environment, reducing the need for frequent replacements and maintenance.

The manufacturer vibrator PU modular sieve also contributes to the sustainability of the mining industry. By improving the efficiency of ore processing, it reduces the amount of waste produced and the energy required for the process. This not only saves money for mining companies but also helps to reduce the environmental impact of mining operations.

In conclusion, the manufacturer vibrator PU modular sieve, or factory shaker urethane fine panel mineral, plays a vital role in the ore processing industry. Its durability, flexibility, and efficiency make it an invaluable tool for miners. As we continue to seek ways to improve the sustainability and efficiency of the mining industry, technologies like the manufacturer vibrator PU modular sieve will undoubtedly play an increasingly important role.