我如何决定使用哪种尺寸的筛网,脱水筛网

العواملالتييجب مراعاتهاعنداختيار حجم الشاشة الشبكية لتطبيقات نزح المياه

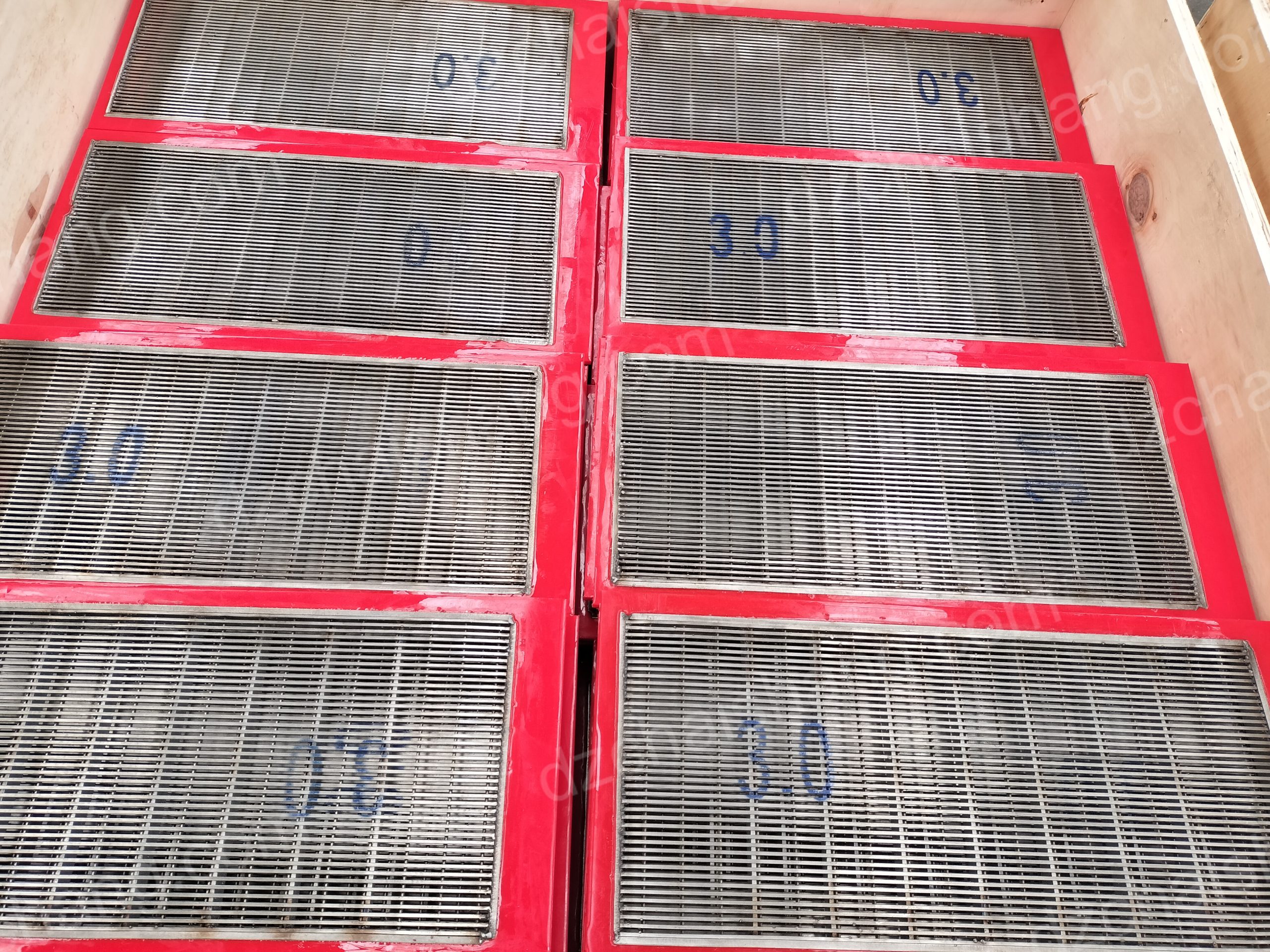

عندمايتعلقالأمر بتطبيقات نزح المياه، فإناختيارالحجم المناسبللشاشة الشبكية يعد أمرًا بالغ الأهميةلتحقيق النتائجالمثلى。 تلعبالشاشةالشبكية دورًارئيسيًافيفصل الموادالصلبةعن السوائل، مما يسمح بنزح المياهبكفاءةمن الموادالمختلفة。 هناك العديد من العوامل التي يجبمراعاتهاعند تحديدحجمالشاشة الشبكيةالمراد استخدامها، بما في ذلك نوع المادة التي تتم معالجتها، وكفاءةنزح المياهالمطلوبة،وحجم الجزيئاتالمراد فصلها.

أحدالعوامل الأساسيةالتييجب مراعاتهاعندالاختيار حجم الشاشة الشبكية لتطبيقات نزح المياه هو نوع المادة التي تتم معالجتها。 تحتوي المواد المختلفة علىأحجاموخصائص جسيمات مختلفة، مما قد يؤثرعلىفعاليةعملية نزحالمياه。 على سبيل المثال، قد تتطلبالموادذات الجزيئات الأكبرشاشة شبكيةخشنةللسماح بالتصريفالمناسب،في حينأنالموادذات الجزيئات الدقيقةقد تتطلب شاشة شبكية دقيقة لمنعالانسدادوضمان نزحالمياه بكفاءة。

بالإضافةإلى نوع المادة التي تتم معالجتها، تعد كفاءة نزحالمياهالمطلوبة عاملاً مهمًا آخر يجب مراعاتهعنداختيارحجم الشاشةالشبكية。 تعملالشاشةالشبكية كمرشح، مما يسمح للمياه بالمرورمعالاحتفاظ بالموادالصلبة。 سيحددحجمالشبكة الشبكيةكميةالمياه التي يمكن تصريفها من المادة، وكذلكمستوى الموادالصلبة المحتجزة。 ستؤدي الشاشةالشبكية الدقيقةإلىكفاءةأعلى في نزح المياه، حيث يمكنهاالتقاطجزيئات أصغر، في حين أن الشاشة الشبكيةالخشنةقدتسمح بتصريفأسرعولكن بكفاءةأقل。

علاوةعلى ذلك، يعد حجم الجزيئات المراد فصلهاأحد الاعتبارات الحاسمة عندمااختيارحجم الشاشةالشبكية لتطبيقاتنزحالمياه。 يجباختيارالشاشة الشبكيةبناءًعلىحجم الجزيئات الموجودةفي المادة، بالإضافةإلى مستوىالفصلالمطلوب。 إذا كانت الجزيئات كبيرةجدًابالنسبة للشاشة الشبكية، فقد لا يتمفصلهابشكلفعال، ممايؤديإلىانخفاض كفاءةنزحالمياه。 منناحيةأخرى،إذاكانت الشاشةالشبكيةدقيقة جدًابالنسبة للجسيمات، فقد تصبح مسدودة، مما يعيق عملية نزح المياه.

منالمهم أيضًامراعاةمعدلتدفق المادةعندتحديدحجم الشاشةالشبكية المستخدمةفيتطبيقات نزحالمياه。 سيؤثرمعدلالتدفقعلى كمية المواد التي تمر عبرالغربالالشبكي، بالإضافةإلىالسرعة التي يمكن أن يحدث بها نزحالمياه。 قد يتطلب معدل التدفق الأعلى شاشة شبكية أكبر لاستيعابحجمالمادة، بينماقديسمحمعدل التدفقالمنخفض باستخدامشاشةشبكية أصغرلفصلأكثردقة。

في الختام، اختيار الحجمالمناسبلشاشة الشبكة لـ تعد تطبيقات نزحالمياهضرورية لتحقيقفصلفعالوفعال للموادالصلبة والسوائل。 منخلالالنظرفيعوامل مثلنوعالمادةالتيتتم معالجتها، وكفاءةنزح المياهالمطلوبة،وحجم الجسيمات،ومعدل التدفق، يمكنكتحديد حجم الشبكة الأمثل لتطبيقكالمحدد。 إنأخذالوقتالكافي لتقييمهذهالعوامل بعنايةسيساعدفيضمان نجاح عمليات نزح المياه وزيادة أداء معداتك إلى أقصىحد。

مقارنةأحجامالشبكات المختلفةللحصولعلى الأداءالأمثللنزح المياه

بالإضافةإلىحجم الجسيماتوكفاءةنزح المياه، فإن المادة التي يتم نزح الماء منها ستلعبأيضًادورًافي تحديدحجمالشبكة الأمثل。 تتميزالموادالمختلفة بخصائصمختلفةلنزح المياه، ويجباختيار حجم الشبكة بناءً على الخصائصالمحددة للمادة。 على سبيل المثال، قد تتطلبالموادذات المحتوىالعاليمن الرطوبةأوالجزيئات الدقيقةشاشةشبكية أكثردقةلتحقيقالأداء الأمثللنزحالمياه。

من المهمأيضًامراعاة قدرةشاشةنزحالمياه عندتحديدحجمالشبكة。 سيسمححجمالشبكة الأكبربإنتاجيةأعلى ونزح المياه بشكل أسرع، ولكنهقديضحيببعض كفاءةنزحالمياه。 علىالعكسمنذلك،فإن حجم الشبكة الأصغر سيوفر كفاءة أفضل في نزح المياهولكنهقديحدمن قدرةشاشةنزحالمياه。 يجب اختيار حجم الشبكة بناءً على التوازن المطلوببينكفاءةنزح المياهوالإنتاجية。

في الختام، يعد اختيار حجم الشبكةالمناسبأمرًا ضروريًالتحقيقالأداء الأمثللنزحالمياه。 يجب اختيار حجم الشبكة بناءً على حجم جسيمات المادة، وكفاءةنزح المياهالمطلوبة، وخصائص المادة التي يتم نزح المياه منها، وقدرة شاشةنزحالمياه。 منخلالالنظربعنايةفي هذهالعوامل،يمكنك تحديدحجمالشبكة الأمثللتطبيقنزح المياهالخاصبكوضمان منتجات نزح المياه عاليةالجودة。

在选择筛孔尺寸时,考虑脱水筛的容量也很重要。较大的网孔尺寸将允许更高的吞吐量和更快的脱水,但可能会牺牲一些脱水效率。相反,较小的筛孔尺寸将提供更好的脱水效率,但可能会限制脱水筛的容量。应根据脱水效率和产量之间所需的平衡来选择筛网尺寸。

总而言之,选择正确的筛网尺寸对于实现最佳脱水性能至关重要。应根据物料的粒度、所需的脱水效率、被脱水物料的性质以及脱水筛的容量来选择筛孔尺寸。通过仔细考虑这些因素,您可以为您的脱水应用选择最佳的筛网尺寸,并确保高质量的脱水产品。