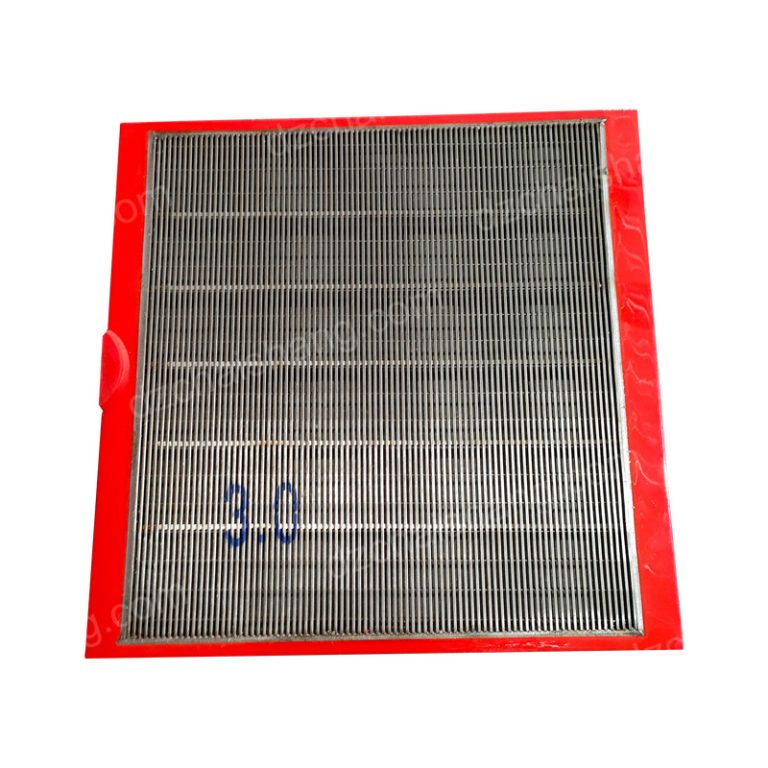

polyurethane mesh sieve

Benefits of Using a polyurethane mesh sieve in Industrial Applications

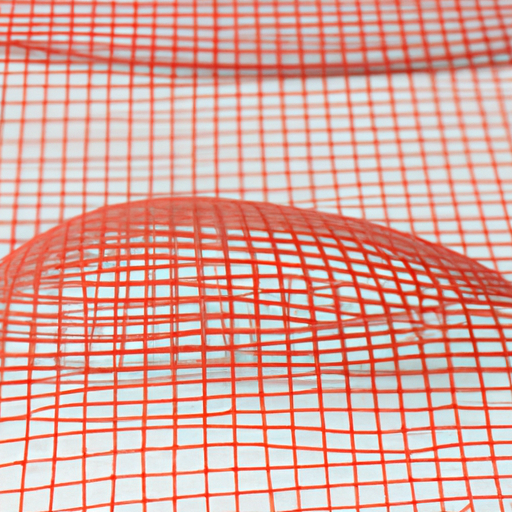

Polyurethane mesh sieves have become increasingly popular in industrial applications due to their numerous benefits. These sieves are made from a durable and flexible material that offers several advantages over traditional metal or nylon mesh sieves. In this article, we will explore the benefits of using a polyurethane mesh sieve in industrial applications. One of the primary benefits of a polyurethane mesh sieve is its durability. Unlike metal sieves, which can rust or corrode over time, polyurethane sieves are resistant to chemicals and moisture. This makes them ideal for use in industries where harsh chemicals or liquids are present, such as the pharmaceutical or food processing industries. Additionally, the flexibility of polyurethane allows the sieve to withstand heavy use without breaking or tearing, ensuring a longer lifespan compared to other materials. Another advantage of using a polyurethane mesh sieve is its ability to provide accurate and consistent particle size separation. The fine mesh openings of the sieve allow for precise separation of particles, ensuring that only the desired size passes through. This is crucial in industries such as mining or construction, where the quality of the final product depends on the uniformity of the particle size. The polyurethane material also prevents clogging or blinding of the sieve, ensuring a continuous and efficient screening process. Polyurethane mesh sieves are also known for their excellent abrasion resistance. The material can withstand the constant rubbing and friction that occurs during the screening process, without showing signs of wear and tear. This is particularly beneficial in industries that handle abrasive materials, such as sand or gravel. The durability of polyurethane ensures that the sieve maintains its integrity and effectiveness, even after prolonged use. In addition to their durability and accuracy, polyurethane mesh sieves offer easy maintenance and cleaning. Unlike metal sieves, which may require special cleaning agents or techniques, polyurethane sieves can be easily cleaned with water and mild detergent. The flexible nature of the material allows for easy removal of trapped particles, ensuring that the sieve remains clean and free from contaminants. This not only saves time and effort but also ensures the hygiene and quality of the final product. Furthermore, polyurethane mesh sieves are lightweight and easy to handle. This makes them convenient for use in various industrial settings, where frequent movement or transportation of sieves is required. The lightweight nature of polyurethane also reduces the risk of injury or strain on workers, making it a safer option compared to heavier metal sieves. In conclusion, the benefits of using a polyurethane mesh sieve in industrial applications are numerous. From its durability and accuracy to its easy maintenance and lightweight design, polyurethane sieves offer several advantages over traditional materials. Industries that require precise particle size separation, resistance to abrasion, and easy cleaning will greatly benefit from the use of polyurethane mesh sieves. As technology continues to advance, it is likely that polyurethane sieves will become even more prevalent in industrial applications, revolutionizing the way materials are screened and separated.