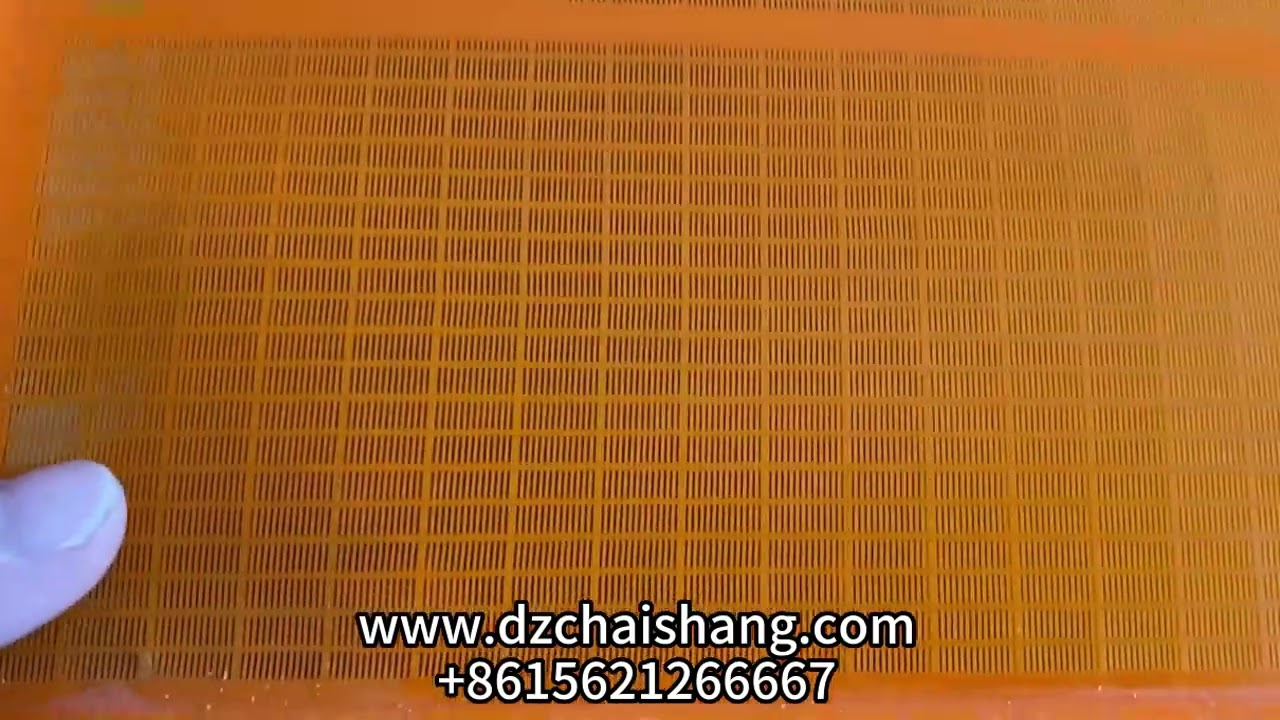

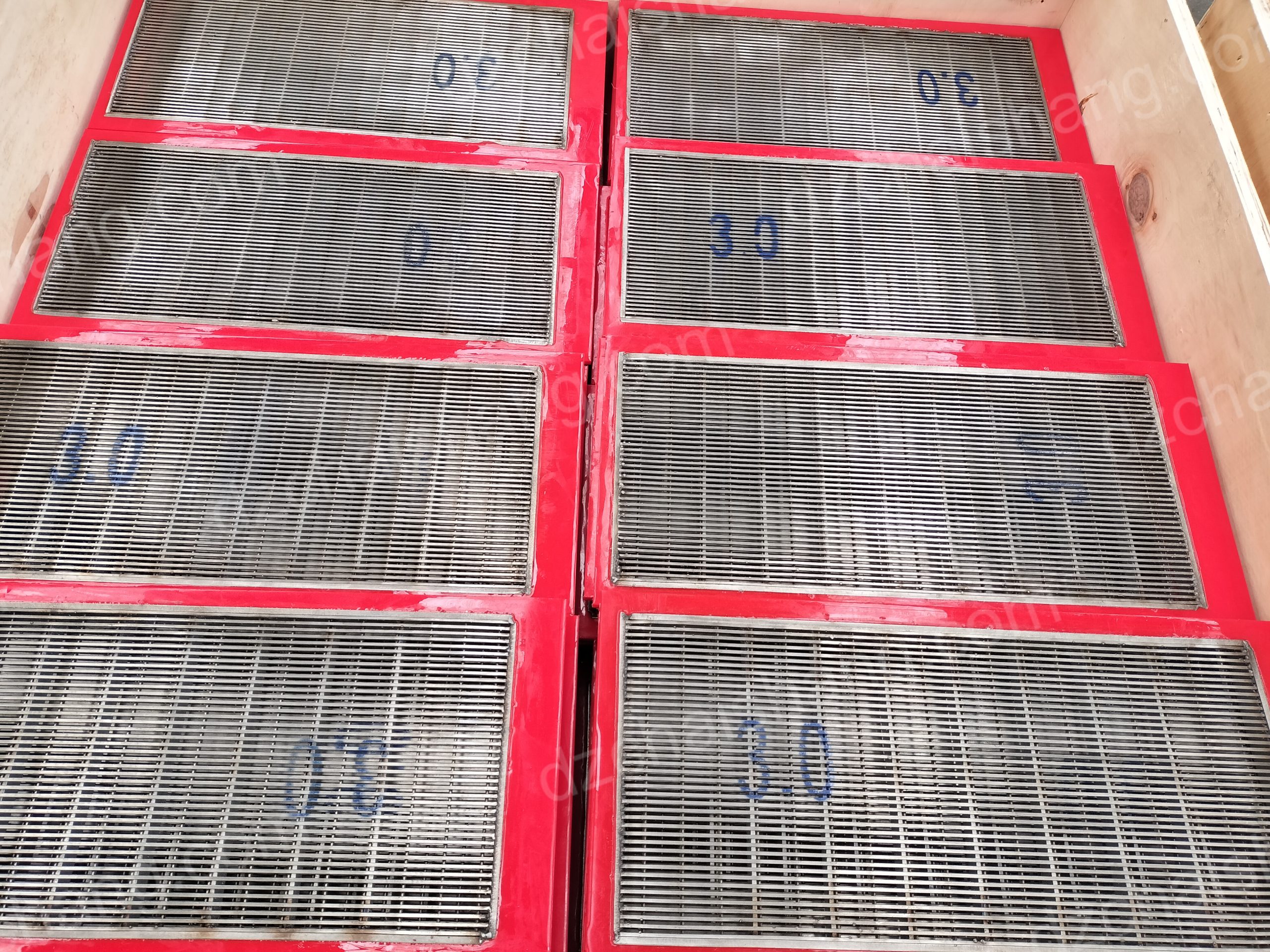

Mesh skrin poliuretana aliran flip berkualiti tinggi untuk skrin bergetar dalam pencucian arang batu

فوائد وتطبيقات شبكة شاشة البولي يوريثين ذات التدفق العالي الجودةفيغسلالفحم

تعد شبكة شاشة البولي يوريثينذاتالتدفق العالي الجودةمكونًا أساسيًافيصناعةغسل الفحم، مما يوفر العديد منالفوائدوالتطبيقات التي تعززكفاءة وفعاليةعمليةالغربلة。 تمتصميمهذاالنوعمن شبكات الغربلةخصيصًا للتعاملمعالظروف الصعبةلغسلالفحم،مما يجعلهخيارًامثاليًا للمشغلينالذين يتطلعونإلىتحسين عملياتهم。

إحدىالفوائد الأساسيةلاستخدام شبكةغربالمنمادة البولي يوريثينذات التدفقالعاليالجودة في الفحم الغسيل هو متانتهالاستثنائية。 مصنوعة من مادة البولي يوريثينعالية المرونة، شبكةالشاشة هذهمقاومةللتآكل،مما يضمنعمرًاأطول مقارنةً بشاشات الشبكات السلكية التقليدية。 تعتبرهذهالمتانةمهمة بشكل خاص في غسل الفحم، حيث يمكن للمواد الكاشطةوالأحمال الثقيلةأنتؤديبسرعة إلىتحللحلولالغربلة الأقلقوة。 باستخدامشبكةشاشةمن البولي يوريثينذات التدفقالعكسي،يمكن للمشغلينتقليلتكاليف الصيانةوتقليلوقت التوقفعنالعمل،مما يؤدي إلى زيادة الإنتاجية والربحية。

بالإضافةإلى متانتها، توفرشبكة الشاشةمنالبولي يوريثينذاتالتدفق العكسي أداء غربلة فائقًا。 التصميمالفريدللشبكة يسمح لهابالتعامل بفعاليةمعالمواد الرطبةواللزجة،والتي يتم مواجهتهابشكلشائع فيغسيلالفحم。 يساعدإجراءالتدفق المقلوبعلىمنع التعميةوالانسداد، ممايضمنبقاءعملية الفحصفعالةودون انقطاع。 يعد هذا أمرًا بالغ الأهميةللحفاظعلى جودةالفحمالمغسول، وكذلكلتحقيقمعدلات الإنتاجية المطلوبة。

ميزةأخرى لشبكةشاشةالبولي يوريثينذاتالتدفق المقلوبهيمرونتها。 يمكنتخصيصشبكة الغرباللتلبية المتطلبات المحددة لتطبيقات غسيلالفحم المختلفة。 يتضمنذلكالاختلافات في أحجام الفتحة وأبعاد اللوحةوالتصميمالعام للشاشة。 منخلالتصميمشبكة الغربلةوفقًا لاحتياجات التشغيل، يمكنللمشغلينتحسين عمليةالغربلة،وتحسين جودةالفحمالمغسول وكفاءةمحطةالغسيل.

تتنوعتطبيقاتشبكة شاشة البولي يوريثين ذات التدفق المقلوبفي غسلالفحموتمتدإلىما هوأبعدمنعمليةالفحص الأولية。 يمكنأيضًااستخدام شبكةالغربلةفي تطبيقات نزح المياه، حيث تساعد على إزالة الماءالزائدمنالفحم المغسول。 تعتبرهذهخطوةأساسية في تحضير الفحم للنقل والبيع، لأنهاتقلل الوزنوتحسنالجودة الشاملةللمنتج。 بالإضافةإلىذلك،يمكن استخدامشبكةالغربلة في عمليات استخلاص الفحم الدقيقة، حيث تساعد في فصل جزيئات الفحمالدقيقةالقيمة عنموادالنفايات。

في الختام، تعد شبكة الغربلةالمصنوعةمن مادةالبولييوريثين عاليةالجودةعنصرًا حيويًافيغسلالفحم، تقدم العديد من الفوائد والتطبيقات التي تعزز كفاءةوفعالية واستدامةعمليةالفحص。 إنمتانتهاوأداءالفحص الفائقوالمرونة والصداقةالبيئية تجعلهاخيارًامثاليًا للمشغلينالذين يتطلعونإلىتحسين عمليات غسل الفحم الخاصةبهم。 منخلالالاستثمارفيحل الفحصالمتقدمهذا، يمكنللمشغلينتحسين جودةالفحمالمغسول، وتقليلتكاليف التشغيل،وتقليل تأثيرهاالبيئي،وكل ذلكيساهمفيصناعةفحم أكثرنجاحًاواستدامة。

翻转流式聚氨酯筛网在洗煤中的应用是多种多样的,并且超出了初级筛分过程的范围。筛网还可用于脱水应用,有助于从洗煤中去除多余的水。这是准备煤炭运输和销售的重要步骤,因为它减轻了重量并提高了产品的整体质量。此外,筛网还可用于粉煤回收过程,有助于从废料中分离有价值的细煤颗粒。

总而言之,高质量的翻转流聚氨酯筛网是洗煤的重要组成部分,提供众多优势和应用,提高筛选过程的效率、有效性和可持续性。其耐用性、卓越的筛分性能、灵活性和环境友好性使其成为寻求优化洗煤作业的运营商的理想选择。通过投资这种先进的筛选解决方案,运营商可以提高洗选煤的质量,降低运营成本,并最大限度地减少对环境的影响,所有这些都有助于煤炭行业更加成功和可持续发展。