Bảng màn hình polyurethane chất lượng cao cho màn hình rung

فوائد استخدام لوحات شاشة البولي يوريثان عالية الجودة

في الختام ، توفر لوحات شاشة البولي يوريثان عالية الجودة العديد من المزايا التي تجعلها خيارًا ممتازًا لشاشات الاهتزاز. إن متانتها ، وكفاءتها ، وفعالية التكلفة ، والتنوع ، وسهولة التثبيت تجعلهم استثمارًا قيمًا لأي صناعة تتطلع إلى تحسين عمليات الفحص الخاصة بهم. مع لوحات البولي يوريثان المناسبة ، يمكن للشركات تحقيق الأداء الأمثل ، وخفض تكاليف الصيانة ، وزيادة عائدها على الاستثمار.

نصائح الصيانة لتمديد عمر لوحات شاشة البولي يوريثان

لوحات شاشة البولي يوريثان هي خيار شائع للشاشات الاهتزازية بسبب متانتها ومرونتها ومقاومة التآكل. تم تصميم هذه اللوحات لتحمل الظروف القاسية لتطبيقات الفحص ، مما يجعلها حلاً فعالًا من حيث التكلفة للعديد من الصناعات. ومع ذلك ، مثل أي معدات أخرى ، تتطلب لوحات شاشة البولي يوريثان صيانة مناسبة لضمان طول العمر والأداء الأمثل. بمرور الوقت ، يمكن أن تتراكم تراكم المواد على سطح الألواح ، مما يقلل من كفاءة الفحص وربما تسبب الضرر. لمنع ذلك ، من المهم تنظيف الألواح بانتظام باستخدام منظف وماء معتدل. تجنب استخدام المواد الكيميائية القاسية أو المواد الكاشطة ، حيث يمكن أن تلحق الضرر بمواد البولي يوريثان. تم تصميم لوحات شاشة البولي يوريثان لتكون متينة ، ولكن لا يزال من الممكن أن تكون عرضة للتهديد مع مرور الوقت. فحص الألواح الخاصة بأي دموع أو ثقوب أو أضرار أخرى ، واستبدال أي لوحات تالفة في أقرب وقت ممكن لمنع المزيد من المشكلات. عندما لا تكون قيد الاستخدام ، قم بتخزين الألواح في مكان بارد وجاف بعيدًا عن أشعة الشمس المباشرة ودرجات الحرارة القصوى. هذا سيساعد على منع الألواح من أن تصبح هشة أو مهينة قبل الأوان. بالإضافة إلى ذلك ، قم بتخزين الألواح في وضع مسطح لمنع التزييف أو التشويه. التوتر المناسب ضروري للفحص الفعال ، لذلك من المهم التحقق من التوتر بانتظام والضبط حسب الحاجة. مع مرور الوقت ، قد يرتفع توتر اللوحات ، مما يؤثر على كفاءة الفحص. استخدم مقياس التوتر لقياس توتر اللوحات وإجراء أي تعديلات ضرورية لضمان الأداء الأمثل. قد يكون لكل مصنع توصيات محددة لتنظيف وتخزين وصيانة ، لذا تأكد من استشارة إرشادات الشركة المصنعة لأفضل الممارسات. يعد التنظيف المنتظم والتفتيش والتخزين المناسب وتعديل التوتر كلها مكونات رئيسية للحفاظ على لوحات شاشة البولي يوريثان. من خلال رعاية لوحاتك ، يمكنك زيادة كفاءتها وطول العمر إلى الحد الأقصى ، وتوفير الوقت والمال في نهاية المطاف على المدى الطويل. تذكر استشارة إرشادات الشركة المصنعة للحصول على تعليمات الرعاية المحددة ، ومعالجة أي مشكلات على الفور لمنع مزيد من الضرر. مع الصيانة المناسبة ، ستستمر لوحات شاشة البولي يوريثان في توفير أداء عرض موثوق به لسنوات قادمة.

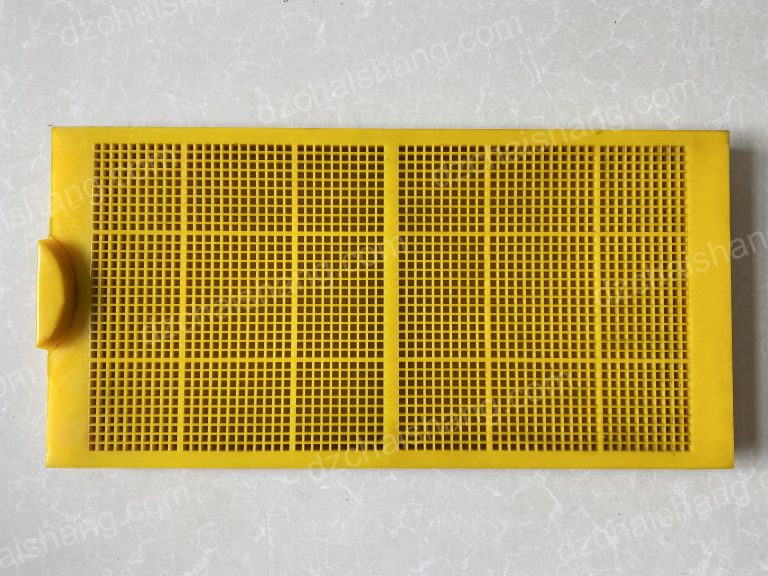

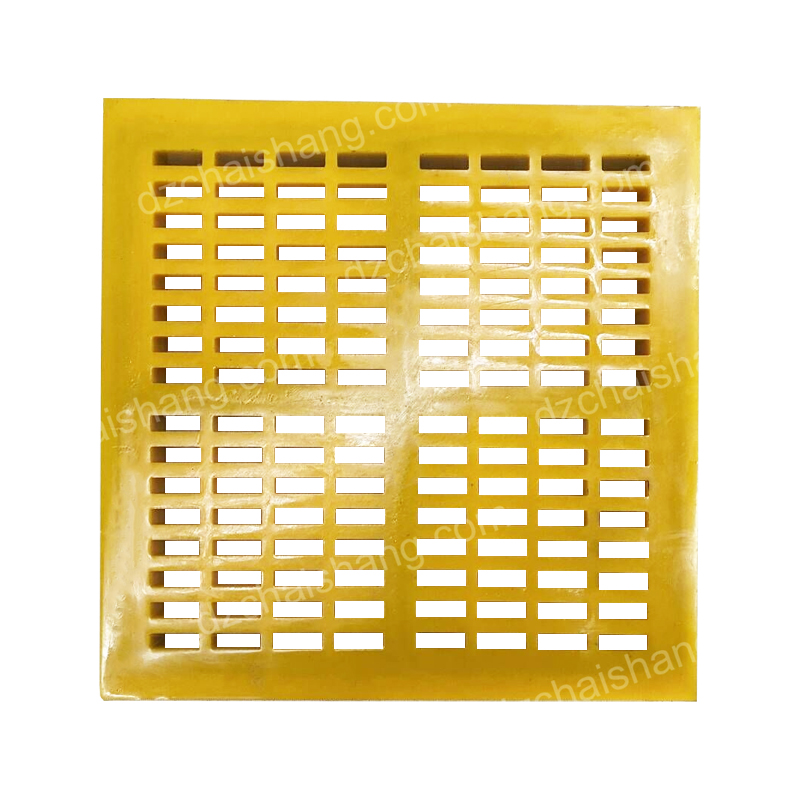

পলিউরেথেনস্ক্রিনতাদের,নমনীয়তানমনীয়তাদক্ষতারস্ক্রিনগুলিরস্ক্রিনগুলিরএকটিজনপ্রিয়জনপ্রিয় এইপ্যানেলগুলিস্ক্রিনিংশর্তগুলিসহ্যজন্যজন্যডিজাইনডিজাইনহয়েছে,传统তিহ্যবাহীতিহ্যবাহীউপকরণগুলিরতুলনায়তুলনায়দীর্ঘতরজীবনকালজীবনকালএবংউন্নতসরবরাহকর্মক্ষমতাকর্মক্ষমতা যখনআপনারস্ক্রিনেরসঠিকপলিউরেথেনপ্যানেলগুলিনেওয়ারকথাতখনআপনিসেরাফলাফলগুলিনিশ্চিতকরারজন্যজন্যবিবেচনাবিবেচনাকরারকরারকারণবেশ অ্যাপারচারআকারটিপ্যানেলেরআকারকে,যাযামধ্যদিয়েপারেকণাগুলিরআকারআকারনির্ধারণ কাঙ্ক্ষিতপৃথকীকরণঅর্জনেরআপনারনির্দিষ্টস্ক্রিনিংজন্যউপযুক্তআকারসহএকটিপ্যানেলপ্যানেলকরা যদিঅ্যাপারচারেরছোটতবেতবেএটিএবংথ্রুপুটহতেহতেহতেহতেথ্রুপুটহতেপারেবৃহত্তরঅ্যাপারচারেরঅ্যাপারচারেরআকারেরআকারেরফলেস্ক্রিনেরমধ্যদিয়েদিয়েপারেপারেপারেপারেপারেপারে অ্যাপারচারেরআকার,পলিউরেথেনপলিউরেথেনপ্যানেলগুলিনির্বাচনসময়বেধআরওএকটিগুরুত্বপূর্ণগুরুত্বপূর্ণ ঘনপ্যানেলগুলিটেকসইউচ্চতরপ্রভাববাহিনীকেকরতেকরতে,তাদেরতাদেরশুল্কস্ক্রিনিংঅ্যাপ্লিকেশনগুলিরজন্যজন্যকরে যাইহোক,ঘনঘনদক্ষতাকরতেপারেপর্দারসামগ্রিকবাড়িয়েবাড়িয়ে,এরতুলতেতুলতেএরপ্রভাবিতপ্রভাবিত সর্বোত্তমফলাফলগুলিনিশ্চিতপ্যানেলবেধএবংদক্ষতারঅপরিহার্যঅপরিহার্য

মডুলার প্যানেল, টেনশনযুক্ত প্যানেল এবং হাইব্রিড প্যানেল সহ বিভিন্ন ডিজাইন উপলব্ধ রয়েছে যা প্রতিটি বিভিন্ন স্ক্রিনিং অ্যাপ্লিকেশনগুলির জন্য অনন্য সুবিধা দেয়। মডুলার প্যানেলগুলি ইনস্টল করা এবং প্রতিস্থাপন করা সহজ, এগুলি এমন অ্যাপ্লিকেশনগুলির জন্য আদর্শ করে তোলে যার জন্য ঘন ঘন প্যানেল পরিবর্তন প্রয়োজন। টেনশনযুক্ত প্যানেলগুলি একটি উচ্চতর স্ক্রিনিংয়ের দক্ষতা সরবরাহ করে এবং উচ্চ-প্রভাব অ্যাপ্লিকেশনগুলির জন্য উপযুক্ত। হাইব্রিড প্যানেলগুলি উভয়ই মডুলার এবং টেনশনযুক্ত প্যানেলগুলির সুবিধাগুলি একত্রিত করে, বিস্তৃত স্ক্রিনিং অ্যাপ্লিকেশনগুলির জন্য একটি বহুমুখী সমাধান সরবরাহ করে

এছাড়াও, স্ক্রিন প্যানেলগুলিতে ব্যবহৃত পলিউরেথেন উপাদানের কঠোরতা বিবেচনা করার জন্য একটি গুরুত্বপূর্ণ বিষয়। উপাদানের কঠোরতা প্যানেলগুলির পরিধানের প্রতিরোধ এবং স্ক্রিনিং দক্ষতাকে প্রভাবিত করে। নরম উপকরণগুলি আরও নমনীয় এবং আরও ভাল প্রভাব প্রতিরোধের সরবরাহ করে, অন্যদিকে শক্ত উপকরণগুলি উন্নত পরিধানের প্রতিরোধ এবং দীর্ঘ জীবনকাল সরবরাহ করে। সর্বোত্তম কর্মক্ষমতা এবং স্থায়িত্ব নিশ্চিত করার জন্য আপনার নির্দিষ্ট স্ক্রিনিং অ্যাপ্লিকেশনটির জন্য উপযুক্ত কঠোরতার সাথে একটি পলিউরেথেন উপাদান চয়ন করা অপরিহার্য

আপনার স্পন্দিত স্ক্রিনের জন্য পলিউরেথেন স্ক্রিন প্যানেলগুলি নির্বাচন করার সময়, প্যানেলগুলির সামগ্রিক গুণমান বিবেচনা করাও অপরিহার্য। ধারাবাহিক কর্মক্ষমতা এবং স্থায়িত্ব নিশ্চিত করার জন্য প্রিমিয়াম-গ্রেডের পলিউরেথেন উপকরণ এবং উন্নত উত্পাদন কৌশল ব্যবহার করে উচ্চমানের প্যানেলগুলি তৈরি করা হয়। আপনার স্ক্রিনিং অ্যাপ্লিকেশনটির জন্য সর্বোত্তম ফলাফলের গ্যারান্টি দেওয়ার জন্য উচ্চমানের স্ক্রিন প্যানেল সরবরাহ করে এমন একটি নামী নির্মাতা চয়ন করা গুরুত্বপূর্ণ। অ্যাপারচারের আকার, প্যানেল বেধ, নকশা, উপাদান কঠোরতা এবং সামগ্রিক মানের মতো বিষয়গুলি বিবেচনা করে আপনি আপনার নির্দিষ্ট স্ক্রিনিং অ্যাপ্লিকেশনটির জন্য সেরা স্ক্রিন প্যানেলগুলি নির্বাচন করতে পারেন। উচ্চমানের পলিউরেথেন স্ক্রিন প্যানেলগুলিতে বিনিয়োগ কেবল আপনার স্পন্দিত স্ক্রিনের কার্যকারিতা উন্নত করবে না তবে এর জীবনকালও বাড়িয়ে তুলবে এবং দীর্ঘমেয়াদে রক্ষণাবেক্ষণের ব্যয় হ্রাস করবে

পলিউরেথেন স্ক্রিন প্যানেলগুলির জীবনকাল বাড়ানোর জন্য রক্ষণাবেক্ষণের টিপস

পলিউরেথেন স্ক্রিন প্যানেলগুলি তাদের স্থায়িত্ব, নমনীয়তা এবং ঘর্ষণ প্রতিরোধের কারণে স্পন্দিত স্ক্রিনগুলির জন্য একটি জনপ্রিয় পছন্দ। এই প্যানেলগুলি স্ক্রিনিং অ্যাপ্লিকেশনগুলির কঠোর শর্তগুলি সহ্য করার জন্য ডিজাইন করা হয়েছে, যা তাদের অনেক শিল্পের জন্য একটি সাশ্রয়ী মূল্যের সমাধান করে তোলে। তবে, অন্য যে কোনও সরঞ্জামের মতো, পলিউরেথেন স্ক্রিন প্যানেলগুলির দীর্ঘায়ু এবং অনুকূল কার্যকারিতা নিশ্চিত করার জন্য যথাযথ রক্ষণাবেক্ষণের প্রয়োজন হয়

পলিউরেথেন স্ক্রিন প্যানেলগুলির জীবনকাল বাড়ানোর জন্য অন্যতম মূল রক্ষণাবেক্ষণের টিপস নিয়মিত পরিষ্কার করা। সময়ের সাথে সাথে, উপাদান বিল্ডআপ প্যানেলগুলির পৃষ্ঠে জমে থাকতে পারে, তাদের স্ক্রিনিংয়ের দক্ষতা হ্রাস করে এবং সম্ভাব্যভাবে ক্ষতির কারণ হতে পারে। এটি প্রতিরোধের জন্য, হালকা ডিটারজেন্ট এবং জল ব্যবহার করে নিয়মিত প্যানেলগুলি পরিষ্কার করা গুরুত্বপূর্ণ। কঠোর রাসায়নিক বা ঘর্ষণকারী উপকরণ ব্যবহার করা এড়িয়ে চলুন, কারণ এগুলি পলিউরেথেন উপাদানগুলির ক্ষতি করতে পারে

পলিউরেথেন স্ক্রিন প্যানেলগুলি টেকসই হওয়ার জন্য ডিজাইন করা হয়েছে তবে এগুলি এখনও সময়ের সাথে পরিধান এবং ছিঁড়ে ফেলার জন্য সংবেদনশীল হতে পারে। যে কোনও অশ্রু, গর্ত বা অন্যান্য ক্ষতির জন্য প্যানেলগুলি পরিদর্শন করুন এবং আরও সমস্যাগুলি রোধ করার জন্য যত তাড়াতাড়ি সম্ভব ক্ষতিগ্রস্থ প্যানেলগুলি প্রতিস্থাপন করুন

পলিউরেথেন স্ক্রিন প্যানেলগুলির জন্য আরও একটি গুরুত্বপূর্ণ রক্ষণাবেক্ষণের টিপ সঠিক স্টোরেজ। যখন ব্যবহার না করা হয়, প্যানেলগুলি সরাসরি সূর্যের আলো এবং চরম তাপমাত্রা থেকে দূরে একটি শীতল, শুকনো জায়গায় সংরক্ষণ করুন। এটি প্যানেলগুলিকে ভঙ্গুর হয়ে উঠতে বা অকাল থেকে অবনমিত হতে বাধা দিতে সহায়তা করবে। অতিরিক্তভাবে, ওয়ার্পিং বা বিকৃতি রোধ করতে প্যানেলগুলি একটি সমতল অবস্থানে সংরক্ষণ করুন

নিয়মিত স্ক্রিন প্যানেলগুলির উত্তেজনা পরিদর্শন করা তাদের কার্যকারিতা বজায় রাখার জন্যও গুরুত্বপূর্ণ। দক্ষ স্ক্রিনিংয়ের জন্য যথাযথ উত্তেজনা অপরিহার্য, সুতরাং নিয়মিত উত্তেজনা পরীক্ষা করা এবং প্রয়োজন অনুযায়ী সামঞ্জস্য করা গুরুত্বপূর্ণ। সময়ের সাথে সাথে, প্যানেলগুলির উত্তেজনা আলগা হতে পারে, তাদের স্ক্রিনিংয়ের দক্ষতা প্রভাবিত করে। প্যানেলগুলির উত্তেজনা পরিমাপ করতে একটি টেনশন গেজ ব্যবহার করুন এবং সর্বোত্তম কর্মক্ষমতা নিশ্চিত করার জন্য কোনও প্রয়োজনীয় সামঞ্জস্য করুন

এই রক্ষণাবেক্ষণের টিপস ছাড়াও, পলিউরেথেন স্ক্রিন প্যানেলগুলির যত্ন এবং রক্ষণাবেক্ষণের জন্য প্রস্তুতকারকের নির্দেশিকাগুলি অনুসরণ করাও গুরুত্বপূর্ণ। প্রতিটি প্রস্তুতকারকের পরিষ্কার, সঞ্চয় এবং রক্ষণাবেক্ষণের জন্য নির্দিষ্ট সুপারিশ থাকতে পারে, তাই সেরা অনুশীলনের জন্য প্রস্তুতকারকের নির্দেশিকাগুলির সাথে পরামর্শ করার বিষয়ে নিশ্চিত হন

এই রক্ষণাবেক্ষণের টিপসগুলি অনুসরণ করে আপনি আপনার পলিউরেথেন স্ক্রিন প্যানেলগুলির জীবনকাল প্রসারিত করতে এবং অনুকূল কার্যকারিতা নিশ্চিত করতে পারেন। নিয়মিত পরিষ্কার, পরিদর্শন, যথাযথ স্টোরেজ এবং টেনশন সামঞ্জস্য হ’ল পলিউরেথেন স্ক্রিন প্যানেলগুলি বজায় রাখার সমস্ত মূল উপাদান। আপনার প্যানেলগুলির যত্ন নেওয়ার মাধ্যমে, আপনি তাদের দক্ষতা এবং দীর্ঘায়ু সর্বাধিক করতে পারেন, শেষ পর্যন্ত দীর্ঘমেয়াদে সময় এবং অর্থ সাশ্রয় করতে পারেন। নির্দিষ্ট যত্নের নির্দেশাবলীর জন্য প্রস্তুতকারকের নির্দেশিকাগুলির সাথে পরামর্শ করতে ভুলবেন না এবং আরও ক্ষতি রোধে তাত্ক্ষণিকভাবে যে কোনও সমস্যা সমাধান করুন। যথাযথ রক্ষণাবেক্ষণের সাথে, আপনার পলিউরেথেন স্ক্রিন প্যানেলগুলি আগত বছরের জন্য নির্ভরযোগ্য স্ক্রিনিংয়ের পারফরম্যান্স সরবরাহ করতে থাকবে