trade shaker Polyurethane fine Deck Dewatering

Pros and Cons of Using polyurethane Coatings in Trade Shaker Equipment

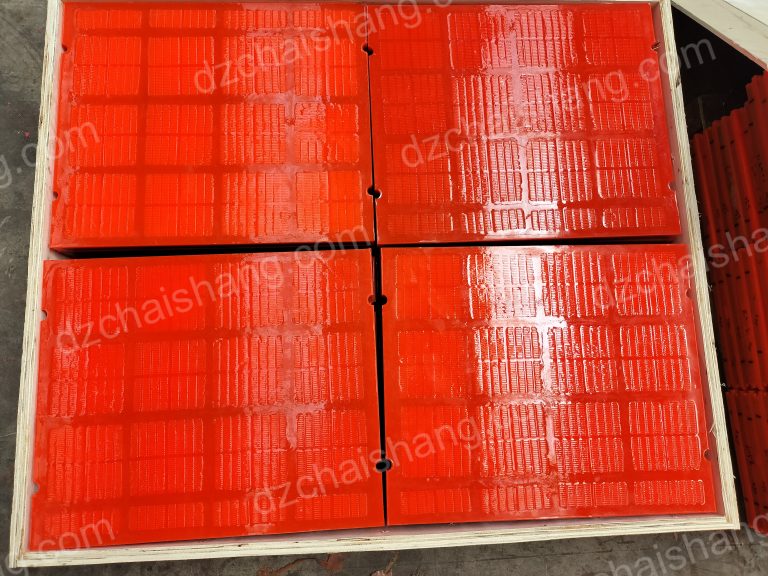

Polyurethane coatings have become increasingly popular in various industries due to their durability, flexibility, and resistance to chemicals and abrasion. In the trade shaker industry, polyurethane coatings are commonly used for deck dewatering applications. These coatings provide a protective barrier that helps prevent corrosion and prolongs the lifespan of equipment. However, like any other material, polyurethane coatings also have their pros and cons when used in trade shaker equipment.

One of the main advantages of using polyurethane coatings in trade shaker equipment is their excellent resistance to water and moisture. Trade shaker decks are constantly exposed to water and other liquids, which can lead to corrosion and rusting of the equipment. Polyurethane coatings create a waterproof barrier that helps protect the deck from moisture, preventing damage and extending the life of the equipment.

Additionally, polyurethane coatings are highly flexible and can withstand extreme temperatures without cracking or peeling. This flexibility allows the coating to expand and contract with the equipment, reducing the risk of delamination and ensuring long-lasting protection. Trade shaker equipment is often subjected to harsh conditions, such as high temperatures and heavy loads, making the flexibility of polyurethane coatings a valuable asset.

Furthermore, polyurethane coatings offer excellent chemical resistance, making them ideal for trade shaker equipment that comes into contact with corrosive substances. These coatings can withstand exposure to acids, alkalis, solvents, and other chemicals without deteriorating, providing reliable protection for the equipment. This chemical resistance helps prevent damage and corrosion, reducing maintenance costs and downtime.

On the other hand, there are some drawbacks to using polyurethane coatings in trade shaker equipment. One of the main disadvantages is the cost of the material. Polyurethane coatings can be more expensive than other types of coatings, which may deter some companies from using them. However, the long-term benefits of polyurethane coatings, such as increased durability and reduced maintenance costs, often outweigh the initial investment.

Another potential downside of polyurethane coatings is their application process. Applying polyurethane coatings requires specialized equipment and trained professionals to ensure proper adhesion and coverage. Improper application can result in poor performance and premature failure of the coating, leading to costly repairs and replacements. Companies considering using polyurethane coatings in their trade shaker equipment should carefully evaluate the expertise and resources needed for successful application.

In conclusion, polyurethane coatings offer numerous benefits for trade shaker equipment, including excellent water resistance, flexibility, and chemical resistance. These coatings can help protect equipment from corrosion, extend its lifespan, and reduce maintenance costs. However, the cost of the material and the complexity of the application process are important factors to consider when deciding whether to use polyurethane coatings. Overall, the pros of using polyurethane coatings in trade shaker equipment outweigh the cons, making them a valuable investment for companies looking to enhance the performance and longevity of their equipment.

How to Properly Maintain and Clean a Polyurethane-Coated Fine Deck Dewatering System

Polyurethane-coated fine deck dewatering systems are a popular choice for many industries due to their durability and resistance to corrosion. However, like any equipment, proper maintenance and cleaning are essential to ensure optimal performance and longevity. In this article, we will discuss how to properly maintain and clean a polyurethane-coated fine deck dewatering system.

Regular maintenance is key to keeping your dewatering system in top condition. One of the most important tasks is to regularly inspect the system for any signs of wear or damage. Look for cracks, chips, or peeling in the polyurethane coating, as these can lead to leaks and reduced efficiency. If you notice any damage, it is important to address it promptly to prevent further deterioration.

In addition to visual inspections, it is also important to regularly check the system’s components, such as the pumps, valves, and filters. Make sure that everything is functioning properly and replace any worn or damaged parts as needed. Regularly lubricating moving parts can also help prevent wear and tear and extend the life of the system.

Cleaning your polyurethane-coated fine deck dewatering system is another important aspect of maintenance. Over time, dirt, debris, and other contaminants can build up on the surface of the system, reducing its efficiency and potentially causing damage. Regular cleaning can help prevent these issues and keep your system running smoothly.

To clean your dewatering system, start by removing any debris from the surface using a soft brush or cloth. Be careful not to use abrasive materials, as these can scratch the polyurethane coating. Once the surface is free of debris, use a mild detergent and water solution to clean the system. Avoid using harsh chemicals, as these can damage the polyurethane coating.

After cleaning the surface, rinse the system thoroughly with clean water to remove any residue. Allow the system to dry completely before using it again. Regular cleaning can help prevent buildup and keep your dewatering system operating at peak performance.

In addition to regular maintenance and cleaning, it is also important to follow the manufacturer’s guidelines for care and maintenance. These guidelines are designed to help you get the most out of your dewatering system and ensure its longevity. By following these guidelines, you can help prevent damage and keep your system running smoothly for years to come.

In conclusion, proper maintenance and cleaning are essential for keeping your polyurethane-coated fine deck dewatering system in top condition. Regular inspections, cleaning, and following manufacturer guidelines can help prevent damage and ensure optimal performance. By taking care of your dewatering system, you can extend its life and save money on repairs and replacements.