vibrating sieve panel efficiency

How to Maximize vibrating sieve Panel Efficiency for Optimal Production

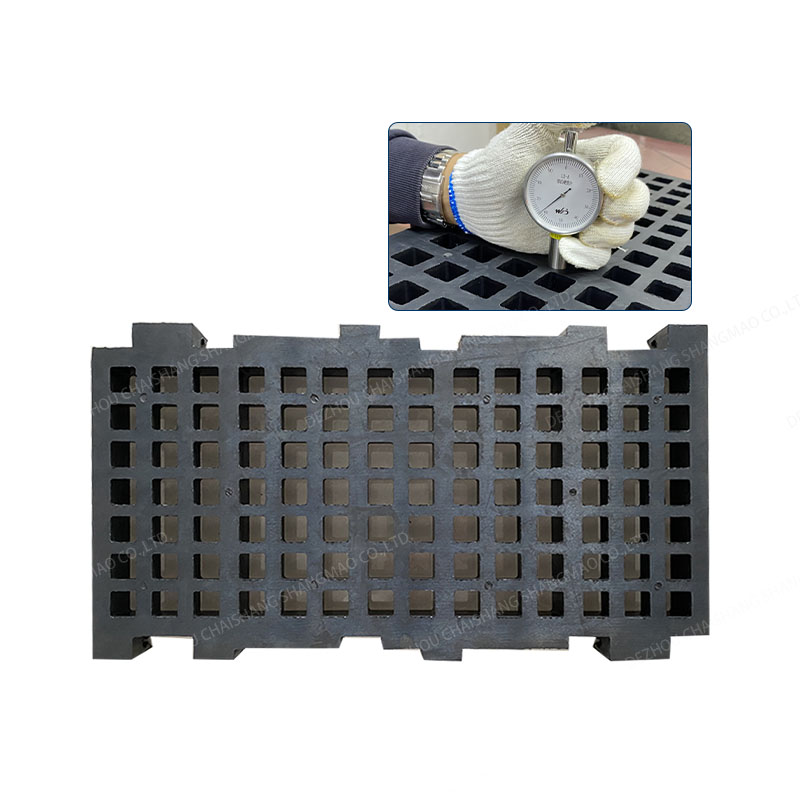

In order to maximize vibrating sieve panel efficiency for optimal production, it is important to consider several factors. First, the sieve panel should be designed to meet the specific requirements of the application. This includes selecting the appropriate size, shape, and material for the sieve panel. Additionally, the sieve panel should be designed to minimize the amount of material that passes through the sieve panel, as this will reduce the amount of material that needs to be processed.

Second, the sieve panel should be properly maintained. This includes regularly cleaning the sieve panel to remove any material that has built up on the surface. Additionally, the sieve panel should be inspected for any signs of wear or damage, and any necessary repairs should be made.

Third, the sieve panel should be operated at the correct speed. This will ensure that the material is properly separated and that the sieve panel is operating at its maximum efficiency. Additionally, the sieve panel should be operated in a manner that minimizes the amount of vibration that is generated.

Finally, the sieve panel should be regularly monitored to ensure that it is operating at its optimal efficiency. This includes checking the sieve panel for any signs of wear or damage, and making any necessary repairs. Additionally, the sieve panel should be inspected for any signs of material buildup, and any necessary cleaning should be performed.

By following these steps, it is possible to maximize vibrating sieve panel efficiency for optimal production. This will ensure that the sieve panel is operating at its maximum efficiency and that the material is properly separated. Additionally, this will help to reduce the amount of material that needs to be processed, resulting in increased production efficiency.

The Benefits of Investing in High-Efficiency Vibrating Sieve Panels for Your Business

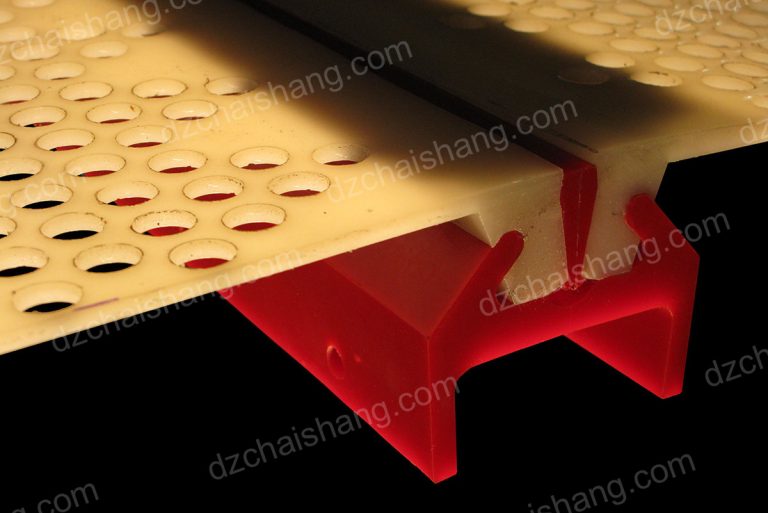

Investing in high-efficiency vibrating sieve panels for your business can provide a number of benefits. These panels are designed to separate particles of different sizes, making them ideal for a variety of industrial applications. By investing in these panels, businesses can improve their efficiency and productivity, while also reducing their operating costs.

The first benefit of investing in high-efficiency vibrating sieve panels is improved efficiency. These panels are designed to separate particles of different sizes quickly and accurately. This means that businesses can process materials faster, resulting in increased productivity. Additionally, these panels are designed to reduce the amount of energy used during the separation process, resulting in lower operating costs.

The second benefit of investing in high-efficiency vibrating sieve panels is improved safety. These panels are designed to reduce the risk of injury to workers. The panels are designed to reduce the amount of vibration and noise generated during the separation process, making them safer for workers to operate. Additionally, these panels are designed to reduce the amount of dust and debris generated during the separation process, making them safer for workers to breathe.

The third benefit of investing in high-efficiency vibrating sieve panels is improved accuracy. These panels are designed to separate particles of different sizes accurately and consistently. This means that businesses can produce higher quality products, resulting in increased customer satisfaction. Additionally, these panels are designed to reduce the amount of waste generated during the separation process, resulting in lower operating costs.

Overall, investing in high-efficiency vibrating sieve panels for your business can provide a number of benefits. These panels are designed to improve efficiency, safety, and accuracy, while also reducing operating costs. By investing in these panels, businesses can improve their productivity and profitability.