Why are problems prone to occur during the use of polyurethane screen plates?

Understanding the Causes of polyurethane screen plate Problems

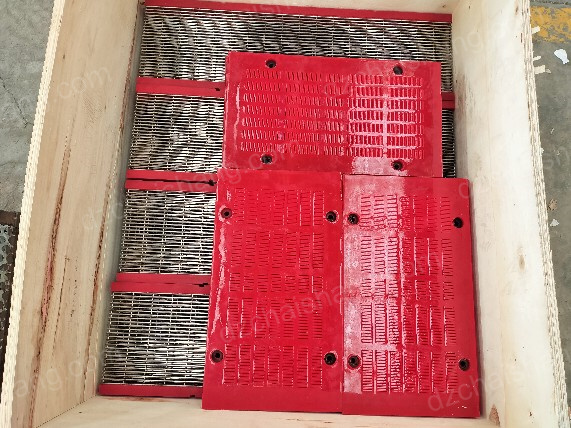

Polyurethane screen plates are an essential part of many industrial processes, but they can be prone to problems. Understanding the causes of these issues can help you take steps to prevent them and keep your operations running smoothly.

The most common cause of polyurethane screen plate problems is improper installation. If the plates are not installed correctly, they can become loose or misaligned, leading to a decrease in efficiency and an increase in wear and tear. To avoid this, make sure to follow the manufacturer’s instructions for installation and use the right tools and techniques.

Another cause of polyurethane screen plate problems is inadequate maintenance. If the plates are not regularly cleaned and inspected, dirt and debris can build up, leading to clogs and other issues. To prevent this, make sure to clean the plates regularly and inspect them for signs of wear and tear.

Finally, improper use can also lead to polyurethane screen plate problems. If the plates are used for tasks they are not designed for, they can become damaged or worn out quickly. To avoid this, make sure to use the plates for the tasks they are designed for and follow the manufacturer’s instructions for use.

By understanding the causes of polyurethane screen plate problems, you can take steps to prevent them and keep your operations running smoothly. With the right maintenance and use, you can ensure that your plates last for years to come.

How to Prevent and Troubleshoot Polyurethane Screen Plate Issues

Polyurethane screen plates are a great way to improve the efficiency of your screening process. However, if not properly maintained, they can cause a variety of issues. Here are some tips to help you prevent and troubleshoot polyurethane screen plate issues.

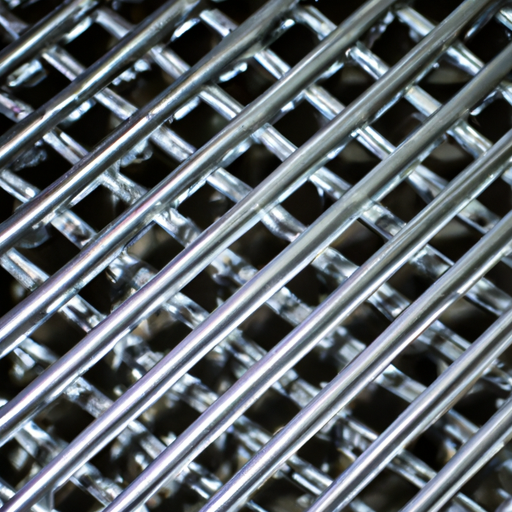

1. Regularly inspect your screen plates for signs of wear and tear. Look for any cracks, tears, or other damage that could affect the performance of the plate.

2. Make sure to clean your screen plates regularly. This will help to prevent any build-up of dirt or debris that could cause problems.

3. Ensure that the tension of the screen plates is correct. Too much tension can cause the plates to wear out faster, while too little tension can cause them to vibrate and cause issues.

4. If you notice any issues with your screen plates, take the time to troubleshoot the problem. Check for any loose bolts or other mechanical issues that could be causing the problem.

5. If the issue persists, consider replacing the screen plates. This will help to ensure that your screening process is running as efficiently as possible.

By following these tips, you can help to prevent and troubleshoot any issues with your polyurethane screen plates. With regular maintenance and inspection, you can ensure that your screening process is running smoothly and efficiently.